In addition to applying Lean Manufacturing principles to on-site construction activities, it is important also to implement those principles to the many construction project management processes. This will help in standardizing those processes, eliminate the tasks that do not add value, make processes as easy as possible for project stakeholders, focus on continuous improvement, automate repetitive tasks and implement metrics to monitor, evaluate and report on the performance of those processes.

Having lean construction management processes will help in eliminating non-value add activities that consume resources but create no value for the project. This will reduce the wasted time and effort that the project team and other stakeholders spend in managing the hundreds of project management processes needed to deliver construction projects.

The Request for Information (RFI) is an example of one of the many project management processes that are usually initiated by the contractor asking for interpretation of item in contract documents. This need for Interpretation is common when contract documents are incomplete, there inconsistency or conflict between more parts of contract documents, insufficient amount of detail to determine design intent, inability for contractor to provide specified product or system, when unknown conditions are encountered when encountering unforeseen conditions such as subsurface soil conditions different from those in geotechnical report, changed existing conditions beyond contractor’s control and concealed conditions different from conditions anticipated by contract documents.

The workflow below details the different manual steps that could take place from the point when an RFI is submitted by the contractor until receiving the consultant response on the RFI. Since the RFI is one of the critical formal communications where it might impact the project’s original scope of work, cost and schedule, the project owner and/or the project management consultant could be involved in the RFI process. The chart details the eight types of waste that could be reduced from each step to increase it is value as well as the overall RFI process value. Those are Defects or Errors for not doing things right the first time, Overproduction when producing more than what is needed, Waiting for time lost when project resources and/or information are not ready, Non-Utilized Staff by not leveraging project resources skills, creativity and talents, Transportation when moving objects from one place to another, Inventory/Storage for unnecessary storage of information or material and Motion for the unnecessary movement of project resources.

Using a Project Management Information System (PMIS) like PMWeb can reduce the waste in performing the RFI process. PMWeb out-of-the-box RFI module can help organizations to create Lean RFI Process that will bring value for the project.

Defects

For steps 1, 3 and 16, instead of using the MS Excel or MS Word to create the RFI, PMWeb comes ready with the RFI template that has all needed fields for WBS, Specification, Phase, Location among others to select from a predefined list of values. In addition, all date fields can be selected from the field calendar. Further, all text fields for question, proposed solution and answer comes ready with spell check as well as allows copy and paste text from other documents. The PMWeb RFI form will also identify the required fields and which fields the specific PMWeb user has access to. This will eliminate date entry errors and missing or incomplete information.

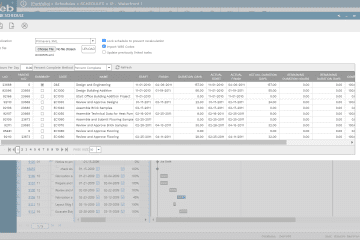

For steps 6, 9 and 21 instead of using the MS Excel to create and maintain a log of RFIs, PMWeb will automatically create a log of all RFI transactions showing the lasted status of each RFI. Different log layouts can be created to display the relevant RFI details as well as filters can be added to limit displayed information which can be sorted and grouped by the different fields. This will eliminate duplicate date entry effort and errors as well as missing or incomplete information.

Motion

For step 2, instead of wasting time in searching for documents, records and emails that need to be sent along with the RFI, PMWeb allows document management repository will be used to create an electronic of all project documents including drawings, specifications, pictures among others. This will allow attaching those documents as well as link other PMWeb records and imported emails to the RFI. This will not only organize project documents for easy access but also enhance collaboration.

Overproduction

For step 13, there is no need for the assigned consultants to meet together to review and respond to the RFI as they all have access to the attached documents where they can be viewed, redlined, add markup, add notes and stamps using PMWeb redline tool. In addition, PMWeb offers an integration with Bluebeam Revu should there be advanced requirements for reviewing, adding remarks and stamping documents. This will allow those consultants to better manage and balance their workload.

Inventory/Storage

For steps 4, 5, 8, 20 and 27 there is no need to print the documents and other records that are attached to the RFI as those can be viewed or downloaded from PMWeb document management repository. PMWeb redline and markup tool will be used to add notes and stamps on those documents. In addition, PMWeb offers an integration with Bluebeam Revu should this be a requirement for reviewing, adding remarks and stamping documents.

Transportation

For steps 7, 10, 26, 28 and 30 the routing of RFI and attached documents is another example of waste associated with the RFI process. When PMWeb is used, the PMWeb email notification will have those documents attached or linked to it. Of course, All those documents are accessible and available to be viewed online. This eliminates the waste associated with physically transporting project documents.

Waiting

For steps 11, 12, 15, 17 and 22 the manual distribution of the RFI to the intended recipients creates unnecessary waiting time which can be reduced by assigning a workflow to the RFI. The workflow will define who should be involved in each step and the time allotted for the step, whether there are multiplier reviewers for the step and if any of the reviewers can approve or all reviewers must approve, action for returning or resubmitting the RFI and should be copied on each step. In addition, conditions can be assigned to the workflow to determine who should be the reviewers depending on the RFI category or specification and if the PMC needs to be involved if the RFI has scope, cost or time impact. This will leverage PMWeb technology to eliminate or reduce hand-offs, clarify processes and ensure compliance with set approval authority levels.

Non-Utilized Staff

For steps 14 and 18, the reviewer of the RFI might require the input of other project team members that are not part of the RFI review process. Seeking the input of those team members without giving access to the RFI under question might not enable them to provide the right feedback that that the reviewer was looking for. Using PMWeb Notification, the review can email the RFI along with attached documents to other project team members whether they have access to PMWeb or not. This will enable engaging those individuals in the review process to improve the RFI review process as well as other related decisions.

Extra Processing

Step 19 is the task where the assigned RFI review determines that the response to the RFI could result in a change for the additional scope of work, cost and time. Instead of wasting the effort in creating a form for the possible change event, PMWeb RFI module can be used to initiate the change event process. This will enable the authorized project team member to determine the needed budget adjustments and estimated commitment change order. This will automatically capture the relevant RFI details in PMWeb change event.

Extra Processing

Step 19 is the task where the assigned RFI review determines that the response to the RFI could result in a change for the additional scope of work, cost and time. Instead of wasting the effort in creating a form for the possible change event, PMWeb RFI module can be used to initiate the change event process. This will enable the authorized project team member to determine the needed budget adjustments and estimated commitment change order. This will automatically capture the relevant RFI details in PMWeb change event.

For step 25, the PCS Engineer can also use the same RFI real-time data across all projects managed by the organization to provide better understanding of RFI performance trends and investigate the possible causes of RFIs and how they can be treated to reduce the likelihood of issuing RFIs.

In conclusion, for organizations who are keep on adopting Lean Manufacturing principles on their projects, they should not limit their effort to on-site construction activities. It is important also to implement those principles to the many construction project management processes that could exceed the 100 processes. This will help in standardizing those processes, eliminate the tasks that do not add value, make processes as easy as possible for project stakeholders, focus on continuous improvement, automate repetitive tasks and implement metrics to monitor, evaluate and report on the performance of those processes.