In today’s construction industry, the pressure to deliver projects on time and within budget has never been greater. Project owners, consultants, and contractors alike are expected to follow best practices in managing risk, performance, and accountability across every phase of delivery. Without a strong foundation in project controls, organizations face escalating costs, missed deadlines, and an inability to justify or defend claims, outcomes that can jeopardize both reputation and profitability.

The truth is simple: in any engineering or construction project, the organization with the weakest project controls bears the highest risk. Without the ability to track performance or verify the source of project data, that organization is not only more likely to suffer losses but also less equipped to recover them.

To mitigate these risks, a robust Project Control System (PCS) is essential. A PCS delivers real-time performance reporting based on a single version of the truth, consolidating data from every corner of the project and tracing it back to its original source. For reporting to be credible, the PCS must integrate all functions critical to project delivery, including document management, scheduling, cost control, risk, change, quality, HSSE, procurement, claims, communication, and progress narratives.

Only by bringing these functions together in a unified system can project stakeholders gain the visibility and control they need to monitor, evaluate, and manage performance with confidence.

What is a project control system?

A project control system is a unified platform that offers the processes, tools, and software to manage a construction project’s key elements. It focuses on three core areas:

- It tracks everything from cost and schedule to quality, compliance, and risk in real time, helping project teams stay on top of what matters.

- It offers a clear, shared view of project performance by pulling data from modules like budgeting, scheduling, procurement, and document control.

- It shares all project-related details in a unified platform to help teams identify issues early and manage them more effectively.

Benefits of using project control systems

A project control system transforms how construction teams handle complex projects. By integrating data and streamlining processes, it helps project leaders deliver on time, within budget, and in line with client expectations.

Here are key benefits of using a PCS:

1. Better project visibility and transparency

A PCS provides stakeholders with real-time access to key project data, such as progress updates, budget consumption, schedule changes, and procurement status. This transparency builds trust and ensures alignment for executives and clients.

For example, if material delivery is delayed or a subcontractor falls behind, the PCS flags it immediately. Teams can then reschedule tasks, reallocate resources, or escalate critical delays before they affect the overall timeline.

Tools like PMWEB offer real-time dashboards and customizable views, so everyone understands project status, risks, and corrective actions underway.

2. Improved schedule and cost control

According to KPMG’s 2023 Global Construction Survey, 61% of firms say a project management information system (PMIS) delivers the highest ROI in capital projects through better cost tracking and reporting.

A PCS enables this by integrating scheduling and budgeting tools, giving real-time visibility into timelines, resource usage, and actual vs. planned costs.

When delays or overruns arise, like a missed phase or supplier price changes, the PCS flags them early.

This visibility is vital in tightly scheduled projects, helping project managers:

- Monitor labor hours and performance

- Track daily progress against key milestones

- Compare current expenses with original estimates or approved changes

These insights allow for faster adjustments to schedules, resources, or vendor terms to keep the project on track..

3. Proactive risk management

Construction projects face risks like labor shortages, weather delays, or design errors. A PCS helps you understand these risks even before they happen and take necessary steps to avert them.

PMWEB’s risk management module lets you log risks in an integrated register, assess their likelihood and impact, and set early-warning alerts..

This enables quick corrective actions, such as adjusting timelines, activating contingency plans, or reallocating resources to ensure the project stays on track.

4. Actionable insights for informed decision making

A PCS collects data from teams, clients, suppliers, turning it into actionable insights for informed decisions.

PMWEB, for instance, integrates with MS Power BI to create real-time, visual reports accessible on any device. If a project phase exceeds labor estimates, the PCS dashboard helps trace the root cause, be it scheduling gaps, delayed supplies, or inefficiencies.

With these insights, teams can quickly resolve issues by reallocating resources or speeding up deliveries..

5. Streamlined communication and collaboration

Construction projects thrive on clear, efficient communication among diverse stakeholders.

In its survey titled ‘The Essential Role of Communications’, published in 2023, the Project Management Institute states that 56% of construction investment is at risk due to poor communication.

Credit - PMI Org

This underscores the importance of effective communication in construction projects. And PCS tools with advanced technologies and easy access make it possible.

Core PCS Capabilities for Total Control of Construction Projects

PCS tools improve this by centralizing real-time updates, documents, and feedback, reducing miscommunication and outdated information.

PMWEB’s lifecycle project management solution centralizes project files, RFIs, and submittals for better collaboration. The capabilities available in PMWEB's comprehensive platform enable portfolio and project owners to plan a construction project, build

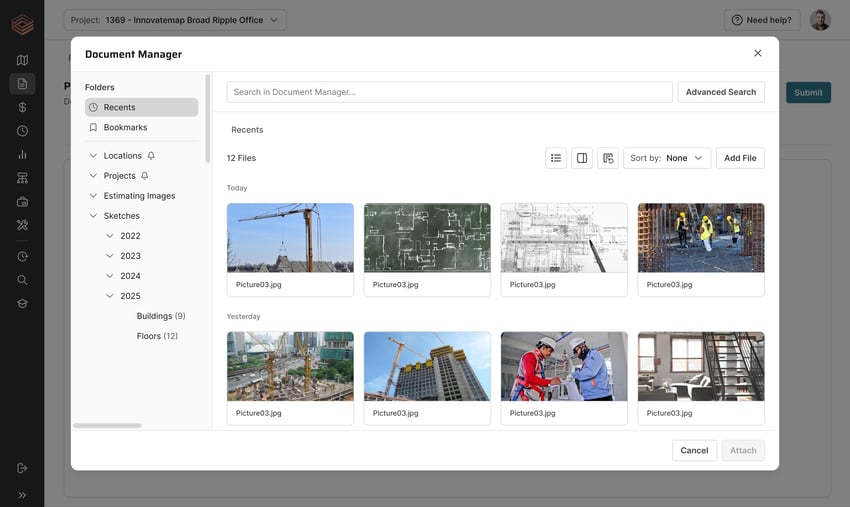

Document Management

The implementation and management of a project control system (PCS) require capturing information from the different project documents as well as storing and using documents and pictures during the project’s execution. Regardless of the project document system used by the project, the PCS team needs to maintain their document system to upload, store and use the documents needed for the PCS.

The documents folder structure used by the PCS team usually aligns with the PCS modules as well as the progress periods. In other words, there are folders used to store and upload the documents that were used to launch the project control system. In addition, there are folders for each progress period to capture the documents and pictures associated with the progress achieved during that period.

The uploading and storing of project documents along with their attributes into PMWeb enables the PCS team to report on their status as well as all revisions made to those documents. In addition, the PCS team can search for documents by using keywords that were either embedded in the file name, added as document attributes, or even included in the content of the uploaded documents as long as the file type is searchable.

Scheduling and Resource Management

In general, a project control system (PCS) is a practice that has originally evolved from the planning and scheduling practice for construction projects. Therefore, managing, monitoring, controlling, evaluating, and reporting a project schedule performance is always a key component of any project control system (PCS). This also explains why integrating all processes of the different PCS functions with the project’s work breakdown structure (WBS) and project schedule activities is a must requirement for an effective PCS.

The baseline project schedule developed by the contractor needs to adhere to the Work Breakdown Structure (WBS) levels included in the project schedule specifications as well as include the interim milestone dates, and interface points with other contractors or external entities included in the project schedule specifications. Of course, the contractor can further detail the WBS levels and add more milestones as well as interface points to have a comprehensive project schedule that can be used to plan the project’s execution as well as monitor, control, evaluate and report on the achieved performance.

For the project’s constraints associated with government permitting authorities such as civil defense, electricity, and water, municipality, and others as well as those permits and approvals issued by professional bodies for structural stability and others, the baseline project schedule should incorporate those constraints in the integrated project schedule plan. The PCS team needs to have access to the current status of those permits and no-objection certificates.

The project schedule for construction projects always includes the requirements for managing labor and equipment resources. The resources loaded on the schedule’s activities help define the labor and equipment resources site deployment requirements during the project’s duration. Unlike other types of projects where resources can be deployed on an as-needed basis, on construction projects, those resources need to be fully deployed on the project. For many countries, the labor resources needed to be employed for each specific project, and government work permits need to be issued.

Of course, the baseline and updated schedule submissions should comply with the project schedule specifications, which are part of the project’s contract documents. A review checklist should be used to verify that the schedule submission complies with the requirements set in the contract documents. Sometimes, the schedule quality review needs to comply with the USA’s Defense Contract Management Agency (DCMA) 14-Point Assessment.

The actual performance of the project’s schedule is reflected in the updated project schedule submissions. The weekly and monthly schedule update submissions should be accompanied by the necessary supportive documents. Those include as a minimum the daily reports formally submitted by the contractor to report the progress on site. The daily reports are usually accompanied by site progress photos. In addition, meeting minutes, submittal register, long lead procurement register, request for information (RFI) register, and other documents might be needed for the schedule update submission.

.png?width=2232&height=1246&name=RFI_Manager%20(2).png)

Budgeting and Cost Management

The work breakdown structure (WBS) becomes the basis for formalizing the project’s scope of work for which it also becomes the basis for estimating the project cost. The cost estimate line items for each WBS level link with the associated project schedule activity to ensure that the scope of work included in the project schedule has been accounted for in full in the cost estimate and vice versa.

The approved cost estimate is a critical component of the project control system (PCS) as it is the basis for establishing the project budget and procurement of the project’s scope of work that will be outsourced.

In addition, the project schedule is loaded by the value of each activity as per the bill of quantity (BoQ) or schedule of values (SoV) of the awarded contract agreement. Those values are known as the selling price values for which they will be known by the project owner, project management consultant, supervision consultant, and contractor. Neither the project owner budget nor the contractor baseline budget will be loaded on the schedule as this is considered to be a confidential document for the parties of the contract.

The cost-loaded schedule helps create the project cash flow and planned early and late dates progress curves. In addition, for some projects, the interim payment certificate (IPC) amount is calculated from the approved percent complete values captured in the project schedule monthly update. For other projects that do not adopt this approach for determining the interim payment certificate (IPC) amount, there is the requirement to measure the actual work in place to determine the amount of the interim payment certificate (IPC).

Regardless of the approach used in assessing the interim payment certificate (IPC) amount, there is always the requirement to formally submit the interim payment certificate (IPC). The submission should include the work inspection requests (WIR), static and rotary equipment inspection checklists, insurances and bonds register, and other checklists to confirm that the contractor has complied with the contract agreement conditions as it relates to the completed works as well as other obligations set in the contract agreement.

The earned value method (EVM) performance reporting is one of the proven methods to report the performance of the project budget and cost. The PCS team uses the project’s baseline budget at completion (BAC) and planned value of budget spending (PV). The planned spending should be aligned with the baseline project schedule. In addition, the PCS team should be provided with details on the revised project budget including details of all adjustments and transfers made to the baseline budget. The project budget excludes the allowances made for the management reserve as well as the profit and home-office overhead which are usually managed at the contractor’s head office.

Risk Management

To address the assumptions made while developing the project schedule, the contractor is required to submit a risk register detailing the identified project risks as per the agreed risk breakdown structure (RBS) or categories. For each risk, the contractor needs to provide the pre-mitigation occurrence likelihood, impact, and exposure, the proposed risk response action to mitigate the risk exposure, and the post-mitigation occurrence likelihood, impact, and exposure. For each identified risk, the contractor needs to identify the Work Breakdown Structure (WBS) level and project schedule activity associated with the risk. This is also a requirement should a Monte Carlo simulation need to be run on the project schedule.

The risk register is also one of the required documents to be submitted along with the baseline schedule as well as periodical schedule updates. The contractor should maintain the risk register and update it with newly identified risks as well as inactive risks.

To manage risks that would occur, which are also known as issues, the PCS team should implement a proactive Early Notification Warning (EWN) to capture the details of those issues and associate them with the risk category that they are associated with. On construction projects that follow the FIDIC 2017 Red Book, there are around thirty-two classifications for those EWNs. Some could entitle the contractor to be compensated for delay, additional cost, or both, or the contractor is not entitled to any compensation. Those early warning notifications that entitle the contract to compensation could lead to a change or variation order to the contract between the project owner and contractor as well as the contract agreements between the contractor and his subcontractors and vendors.

Change Management

The project control system (PCS) needs to report on all changes to the original project’s scope of work. There are many reasons for project changes including those that have resulted from the early warning notifications (EWN) or potential changes or changes that are directed by the project owner. Changes that could be classified as in-scope or out-of-scope changes could have an impact on the project’s completion, budget at completion, or both.

The PCS should enable reporting on all potential changes, approved, pending, and disputed commitment change/variation orders, budget adjustments, and change events to associate commitment changes with their relevant budget adjustments. In addition, the PCS change management module should report on the changes for revenue or income contracts. Examples of revenue contracts are the contract agreement between the contractor and project owner if the PCS was managed by the contractor, the agreements that project owners have with buyers of the project assets or having long-term lease agreements, or the agreements that the Special Purpose Vehicles (SPV) have on PPP projects for benefits realization.

Quality Control

To justify the actual completed work in place reported in the updated schedule, the PCS team needs to have access to the work inspection requests (WIR), material inspection requests (MIR), concrete pouring reports, inspection requests for rotary and static equipment, and other related transactions of quality control processes. In addition, the PCS team needs to have access to all non-compliance reports (NCR) issued to the contractor and for which have an impact on the project’s progress.

The integrated project schedule should also include the many tasks needed for the project’s testing and commissioning before it can be considered substantially completed and can be occupied by the end-users. The beneficial occupancy, the building is sealed, energization, HVAC balancing, and other testing and commissioning milestones are examples of the milestones that a project owner might require the contractor to incorporate into the integrated project schedule. The PCS team needs to have access to the pre-startup, functional and performance, pre-energization, and pre-commission inspection checklists to update the testing and commissioning activities.

HSSE

The PCS team needs also to have details of the Health, Safety, Security, and Environment (HSSE) functions. The contractor could be stopped from doing work on the project if the contractor fails in complying with the HSSE practices implemented on the project. As a minimum, the PCS team should have a register of all safety incidents and safety violations issued to the contractor. The data captured from the reported safety incidents and labor manhours captured in the daily report becomes the basis for reporting the Lost Time Injury (LTI), Lost Time Injury Frequency Rate (LTIFR), and Lost Time Injury Severity Rate (LTISR) measures.

Procurement

The dates for the contractor to procure material, equipment, and subcontract services should be aligned with the dates set in the integrated project schedule. Accordingly, the PCS team should be made aware of the planned dates for the issuance of tender queries for the outsourced scope of work, award of those contracts, and actual deliveries to the construction site. For long lead equipment and material items, the PCS team needs to have details of the manufacturing dates, factory testing, shipping, arrival dates, site delivery dates, and site testing and acceptance.

The details of all selected subcontractors and vendors should become part of the project directory that the PCS Team would usually maintain for the project. The directory includes the contact details for the project owner, project management consultant, design and site supervision consultants, other consultants, contractors, fire brigades, nearby hospitals, subcontractors, vendors, and other project stakeholders.

Claim Management

Since it rarely happens that a construction project completes without having the risk of claims, the PCS team needs to support the contract team in preparing the delay analysis associated with the claim event using what is known as the Time Impact Analysis (TIA). In addition, the PCS team might also need to provide the details for lost productivity claims using what is known as the Window-Analysis. The summary of that analysis is usually summarized in what is known as the Extension of Time (EOT) submission.

Communication and Interfaces

The time-impact and lost-productivity analysis usually requires the PCS team to have access to project communication associated with the different claim events. These could include the Request for Information (RFI), Site Work Instructions (SWI), Confirmation of Verbal Instruction (CVI), Engineer’s Instruction (EI), Correspondence, Email Communications, Meeting Minutes, and other types of project communications.

In addition, the PCS team would need to have access to the project’s document management systems where project documents are stored in the designated folders. The PCS team might need to search those documents for records that are associated with the claim events being finalized.

Similar to all other project groups, the PCS team might have its internal meetings or meetings for project progress review and other related PCS functions. In addition to the meeting minutes that are generated for the different meeting types, the PCS team would have many informal or ad-hoc internal meetings or meetings with other stakeholders. Unlike the online meetings like those with MS Teams, Zoom, and other platforms, the PCS team ad-hoc meetings have different actions that those who have a role in those meetings need to update and provide details on whether other PCS team members were online or not.

For projects where multi-prime contractors are involved in delivering the construction project, reporting the status of all interface points is one of the tasks that the PCS team must perform. The integrated project schedule should include activities for all internal and external interfaces. The duration of those activities represents the duration needed to carry out all inspections, documentation, and approvals of those interfaces.

Narrative

Another requirement for the PCS team is the function of capturing what is known as the progress narrative, which the PCS team uses to explain the different progress reports that they need to share with the different project stakeholders. This requires having pre-defined templates that allow the PCS team to provide the content for the different sections of the progress reports. In addition, those progress templates should have data fields with a predefined list of values to standardize the reporting of project performance.

How AI and Predictive Analytics Are Shaping PCS

In its report titled ‘The State of AI in Project Management’, Capterra says that 91% of businesses that have invested in AI in project management have reported positive ROI in one year.

AI and predictive analytics are revolutionizing project control systems by offering advanced tools to make construction management more data-driven.

Here is how these technologies are transforming PCS:

- AI-powered PCS analyzes historical project data, weather, and resource availability to create optimized schedules and identify potential bottlenecks.

- Predictive analytics enhances cost estimates using past project costs, market trends, and site-specific variables to offer early warnings of budget risks.

- AI integrates with IoT devices to provide real-time insights and make changes accordingly.

- AI-driven PCS tools improve risk management by identifying issues based on sensor or performance data.

- AI and predictive analytics promote sustainable construction by optimizing material usage and energy consumption.

Improve your project performance with PMWEB

For construction projects with numerous moving parts, having a robust, reliable, and advanced project control system is vital.

A feature-rich and robust PCS tool like PMWEB can help project leaders track progress, manage budgets, allocate resources, and anticipate risks.

PMWEB brings the following features to keep project leaders informed about diverse aspects of a project:

- Visual workflow platform: PMWEB’s customizable workflow engine automates processes like approvals and RFIs. It integrates with tools like DocuSign to reduce errors and shorten approval cycles.

- Single database integration: PMWEB’s unified, web-based database consolidates schedules, costs, and documents. Integration with tools like Primavera and BIM minimizes silos and reduces cost overruns.

- Advanced cost management: PMWEB supports precise budget and forecast tracking through user-defined cost worksheets and drill-down analytics for improved budget controls

Use PMWEB with these project controls checklists to improve oversight and maintain project alignment.

Frequently asked questions

What is a project control system in construction?

A PCS in construction tracks and manages cost, schedule, and performance data throughout a project’s lifecycle. It ensures transparency, accountability, and informed decision-making.

How does PCS differ from project management software?

While project management software focuses on managing tasks and teams, a PCS emphasizes real-time control of costs, schedules, and risks specific to construction.

What modules are included in a PCS?

Typical PCS modules include cost management, scheduling, risk management, document control, contract administration, procurement, change management, and performance reporting.

Can PCS integrate with BIM or ERP systems?

Yes, PCS tools can integrate with platforms like ERP, BIM, CRM, and scheduling tools. For example, PMWEB integrates with both BIM and ERP systems for centralized workflows and real-time insights.

Why choose PMWEB as a project control solution?

PMWEB is an all-in-one and scalable platform with extensive cost, schedule, and document control.It is also highly configurable and integrates with BMI, ERP, CRM, scheduling, and accounting tools.

Reference

The content of this article was extracted from the book titled “Let’s Transform: Enabling Digital Transformation of Capital Construction Projects Using the PMWeb Project Management Information System – 2nd Edition”. The book was written by the author of the posted article, Bassam Samman.

The book provides project owners with oversight on how technology available today can support their efforts to digitally transform the management of their projects’ portfolios. For each capital project life cycle stage, PMWeb is used to detail how the relevant project management business processes can be digitalized to enforce transparency and accountability in delivering projects. In addition, MS Power BI was used to show how the real-time, trustworthy data captured in PMWeb can be aggregated, modeled, monitored, evaluated, analyzed, and reported on anytime, anywhere using any device.

.png?width=640&height=360&name=SOC%20Blog%20Banner%20(1).png)