The Work Inspection Request (WIR) is one of the quality controls processes that need to be monitored, evaluated, and reported in the project control system (PCS). This process is important for verifying and approving the work in place included in the monthly interim payment certificate (IPC) application.

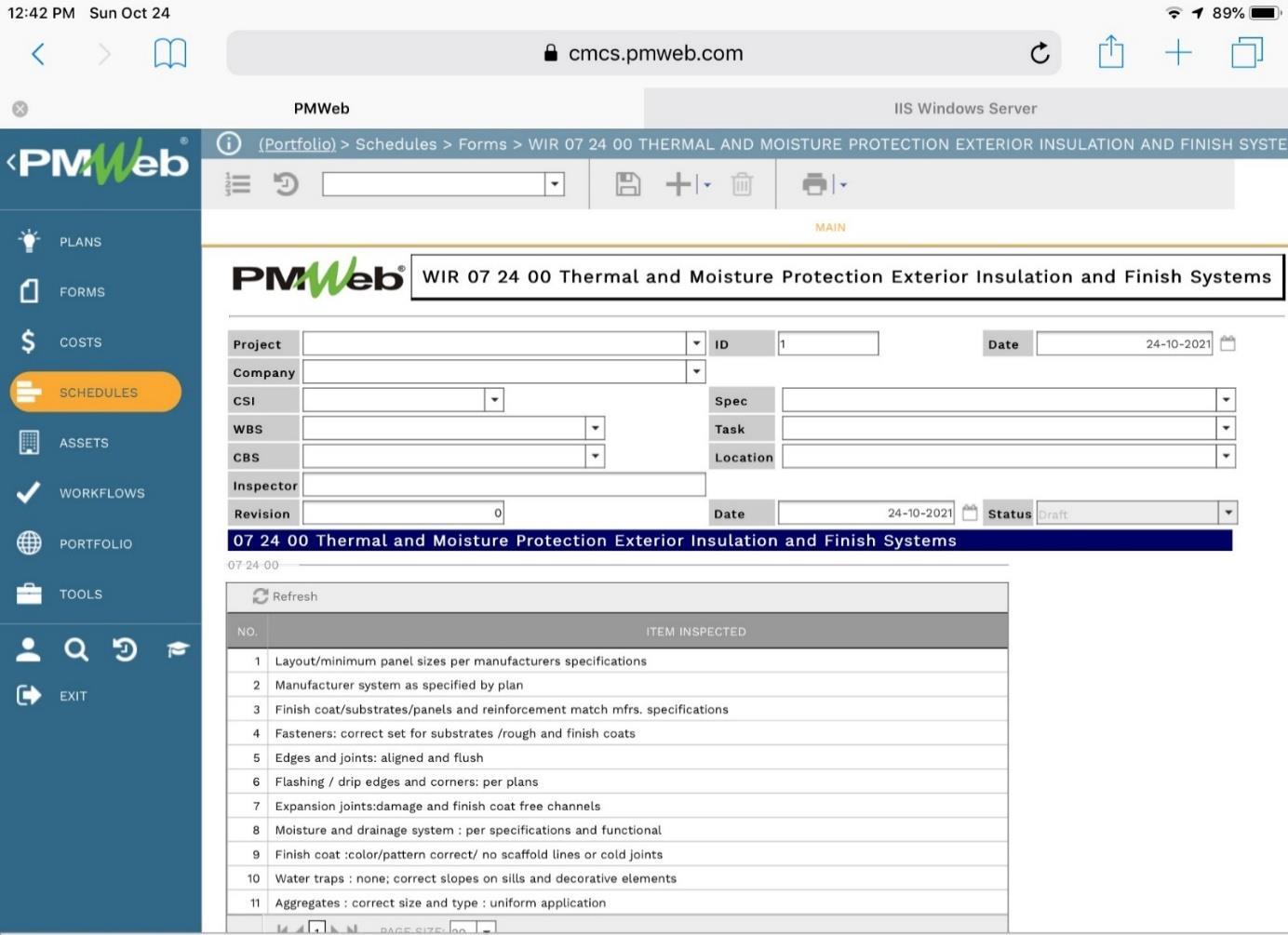

One of the proven best practices for inspecting the contractor’s completed work in place is the use of checklists that identify all items to be inspected by the site supervision consultant before they are approved or rejected. These checklists need to be based on the project’s specification documents which could differ from one project to another, depending on each project’s quality standards.

Checklists are crucial to ensure the inspection has been completed as specified and to eliminate arguments between the engineer and contractor on what is being inspected and the level of inspection. The value of these checklists can be maximized when the contractor first uses them to accept the work from his team or subcontractors. If all work has been done by what is specified, then the contractor can proceed and submit for the site supervision consultant’s review and approval.

The PMWeb visual custom form builder helps to develop the different templates for WIR checklists required for projects. The content of these checklists should align with what has been specified for the project. PMWeb allows accessing these WIR online using any smart mobile device. These devices also enable the user to take pictures and videos and attach them to the WIR.

A workflow gets assigned to the WIR form which will be submitted by the contractor’s team member requesting the inspection to the site supervision consultant for approval. The site supervision consultant decides if the inspection can be done as is or be returned to the contractor to rectify all failed items and resubmit.

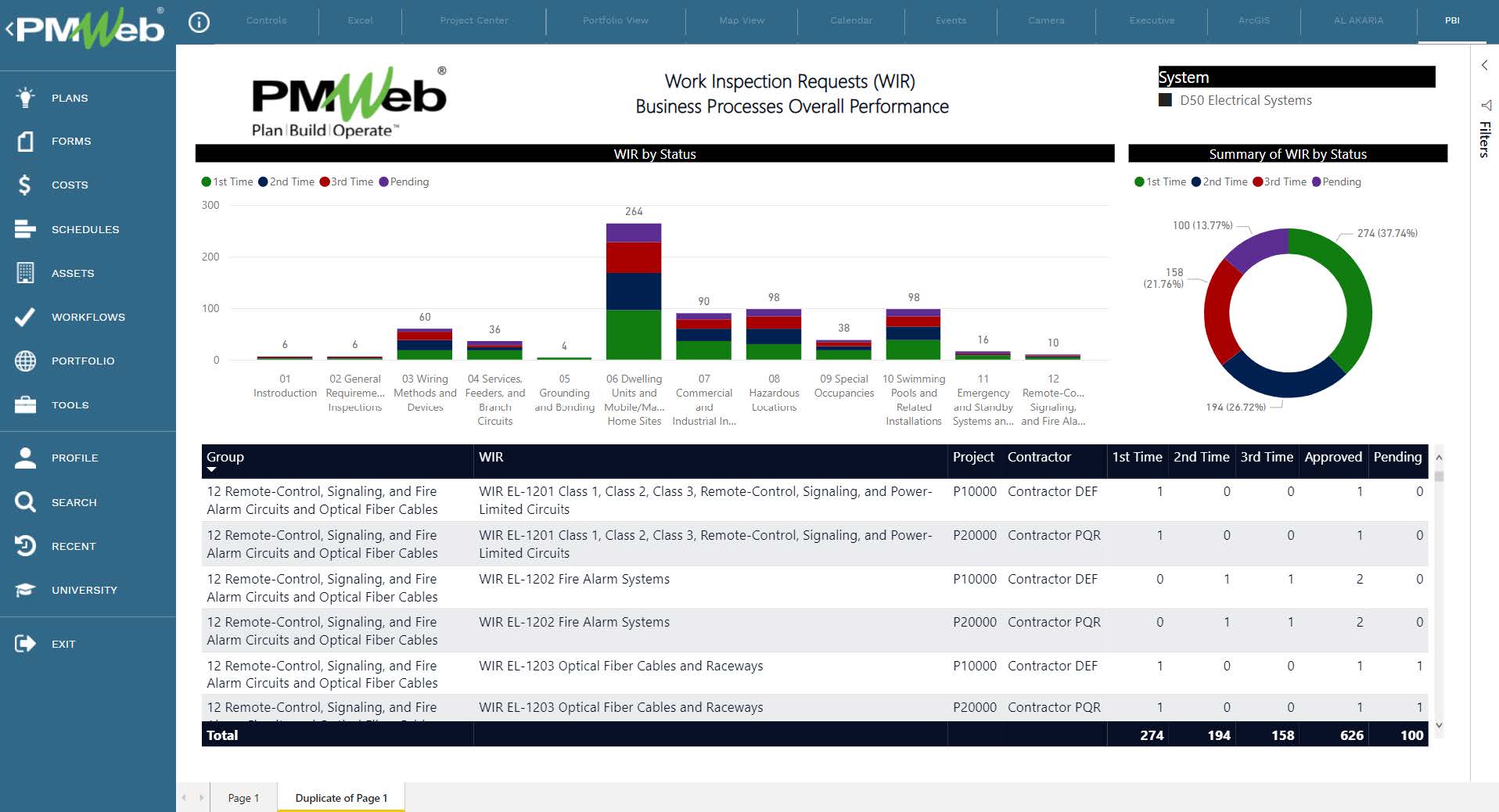

Another example will be the WIR for the electrical scope of work (SoW). The Electrical Inspection Manual has identified 77 electrical inspection checklists that could be used on capital construction projects to ensure compliance with the National Electrical Code® (NEC) rules (Williams, Sargent, & Jones, 2014). The National Electrical Code® (NEC) code provides details of all inspection requirements for the electrical systems on a project.

Using the PMWeb visual custom form builder, templates for all types and categories of WIR for all building systems can be created. These templates not only ensure that all completed work on site has been done, inspected, and approved by what had been specified, but also enable capturing, documenting, and using the immense knowledge associated with these inspections across the complete projects’ portfolio that the Project Owner has.

The checklist table is unique for each WIR template, including the items specific to each system or component being inspected. For example, for the 77 electrical inspection checklists of the 12 groups as outlined in the above-referenced document, there are 77 unique templates to detail what items are to be inspected for each electrical component. The table includes the items to be inspected for each WIR checklist, specification reference for the item to be inspected, inspection status, and inspection remarks if any.

The data captured in the Work Inspection Requests (WIR) forms creates the WIR Performance dashboard. This dashboard includes a log for all WIR made from the selected project specification divisions. The dashboard also includes visuals to group WIR by specification divisions, the location where the inspection was made, and the company that has initiated the inspection request. Of course, the layout and format of the dashboard can be designed in other desired formats depending on the organization’s performance reporting requirements.

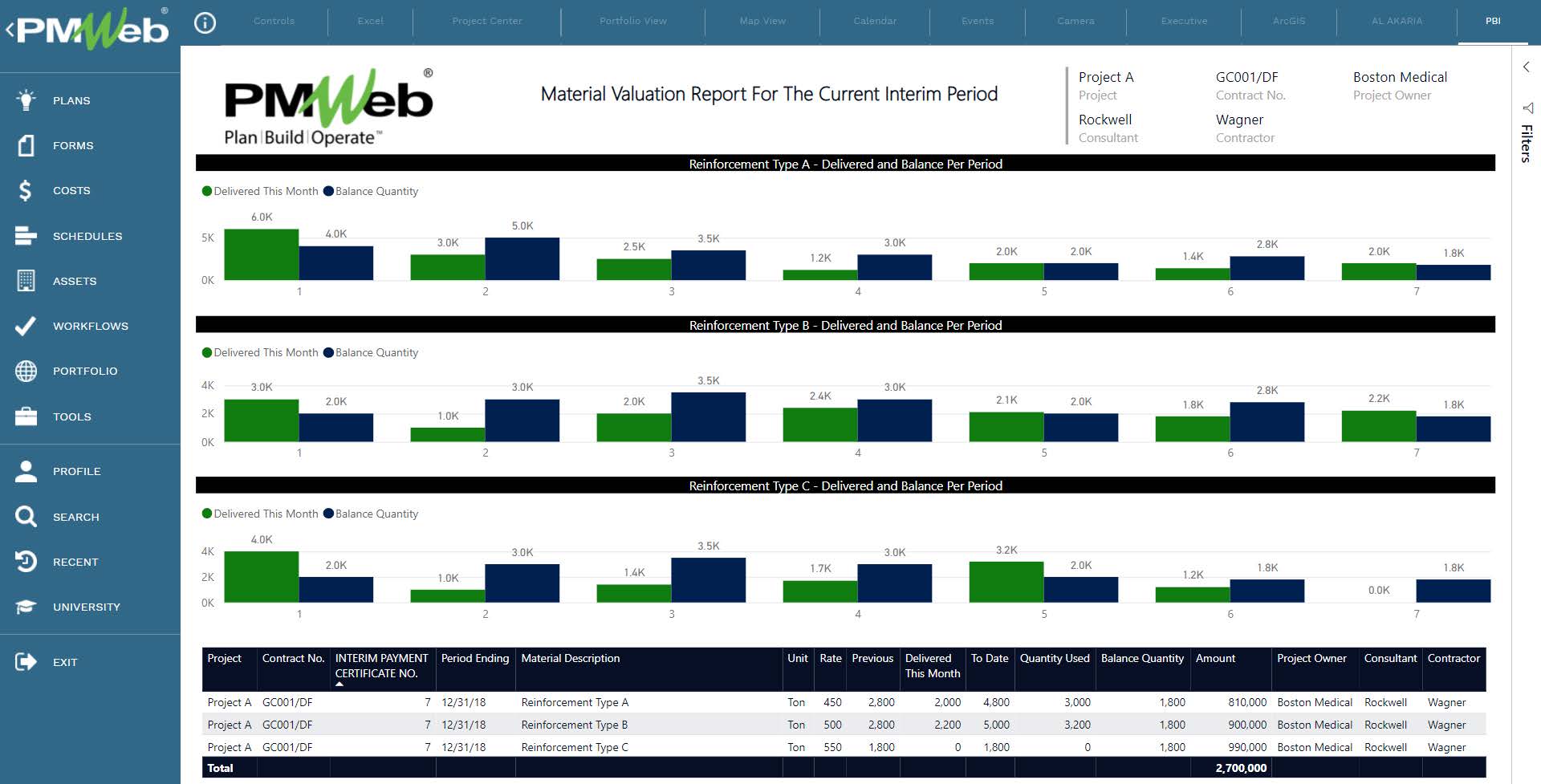

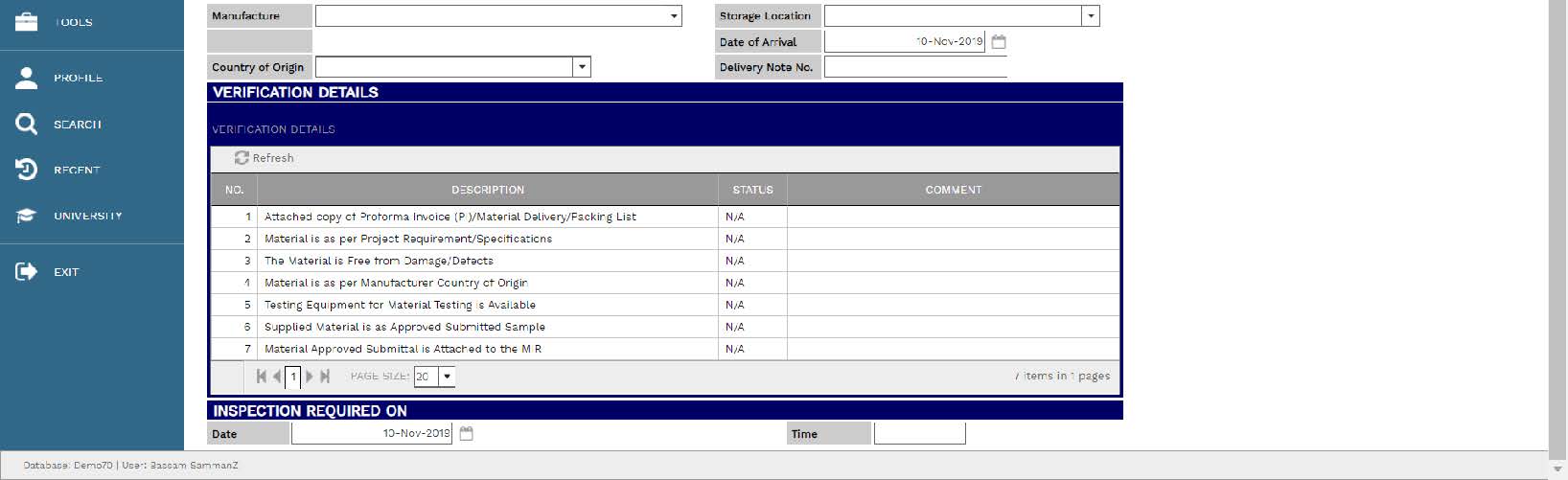

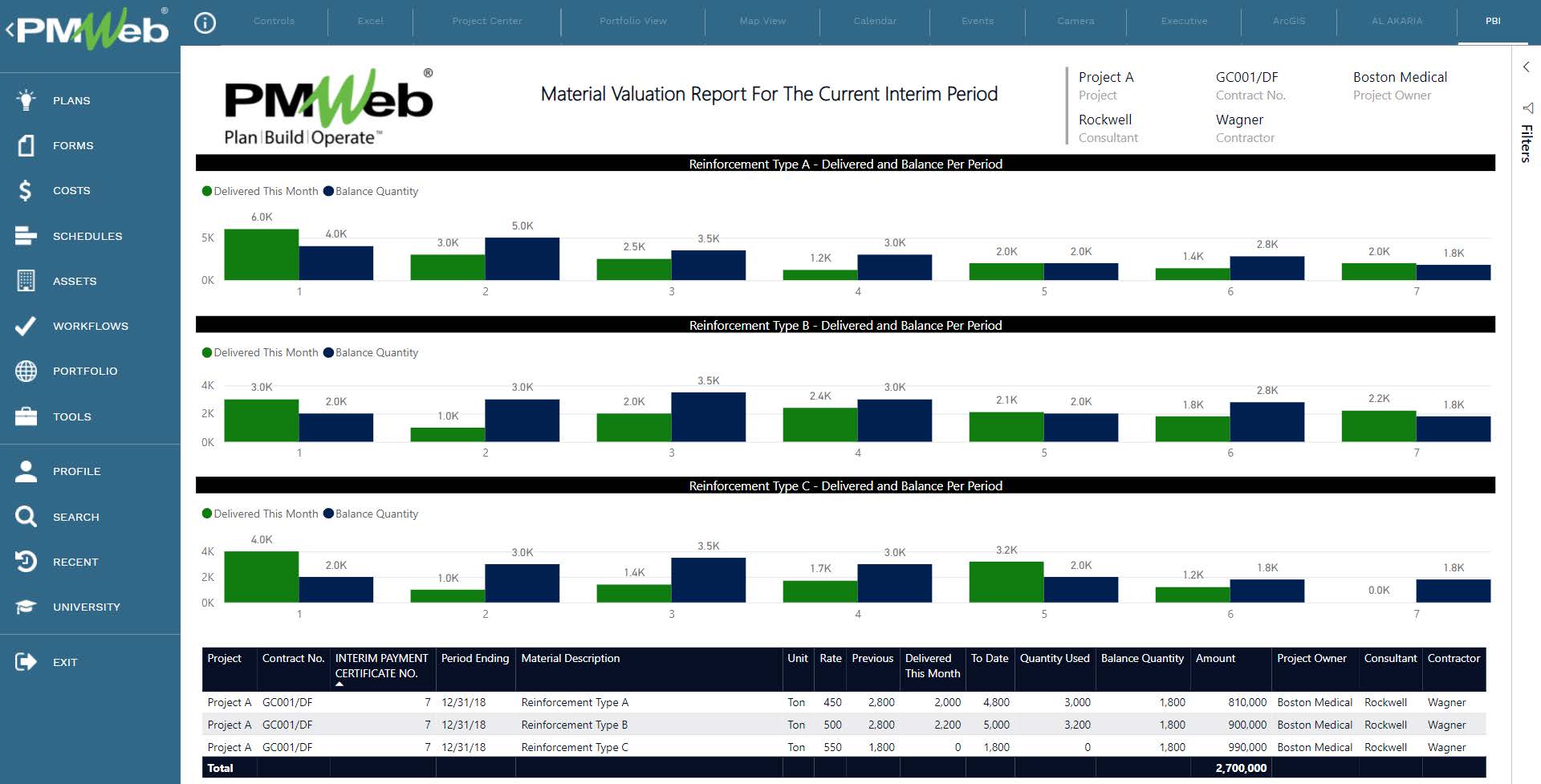

Another quality control process that needs to be monitored, evaluated, and reported in the project control system (PCS) is the material inspection requests (MIR). A contractor needs to include those inspection requests when creating the monthly interim payment certificate, a payment request for materials stored on site.

The PMWeb custom form builder develops the template for another quality control business process managed in PMWeb, which is the Material Inspection Report (MIR). The template can include the data fields needed to capture the details of the material deliveries and storage and the details of the material manufacture. The MIR form includes a checklist to detail items that must be verified against the delivered material.

The data captured in the stored materials for the different project periods provides the Project Owner and another stakeholder with information on material deliveries that have taken place during the project duration and the materials stored at the project site. The content and layout for the form can be modified to reflect the project’s reporting requirements.

Reference

The content of this article was extracted from the book titled “Let’s Transform: Enabling Digital Transformation of Capital Construction Projects Using the PMWeb Project Management Information System – 2nd Edition” written by Bassam Samman.

The book provides project owners with oversight on how technology available today can support their efforts to digitally transform the management of their projects’ portfolios. For each capital project life cycle stage, PMWeb is used to detail how the relevant project management business processes can be digitalized to enforce transparency and accountability in delivering projects. In addition, MS Power BI was used to show how the real-time, trustworthy data captured in PMWeb can be aggregated, modeled, monitored, evaluated, analyzed, and reported at anytime, anywhere using any device.