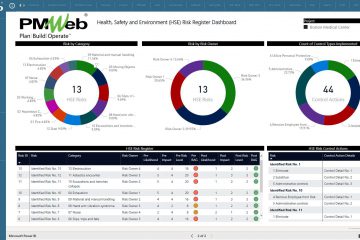

Those who are set accountable for developing and maintaining the Health, Safety, and Environment (HSE) Risk Register need to know what the probable causes of HSE risks are, their likelihood to occur, and their impact on the project’s human resources, progress on-site and project cost. This information could vary from one country to another and sometimes between one entity and another. Nevertheless, regardless of where this risk assessment is being done and by which entity, having a comprehensive and meaningful HSE risk assessment depends on the quality of the captured data that will be the basis for the information used in the assessment. Organizations need to implement a solution to capture the data associated with the safety incidents that have actually occurred on their projects. This is the only way that an organization can have access to trustworthy, traceable, auditable, and real-time data that can be used in their HSE risk assessment and registration process.

Since the needed data mainly relates to the actual safety incidents that could have occurred on construction sites, then the safety incident form should provide the best business process to capture this data. The safety incident form needs to be aligned with the HSE Risk Assessment and Register Report to enable using the captured data to improve the risk assessment process needed to develop the risk register.

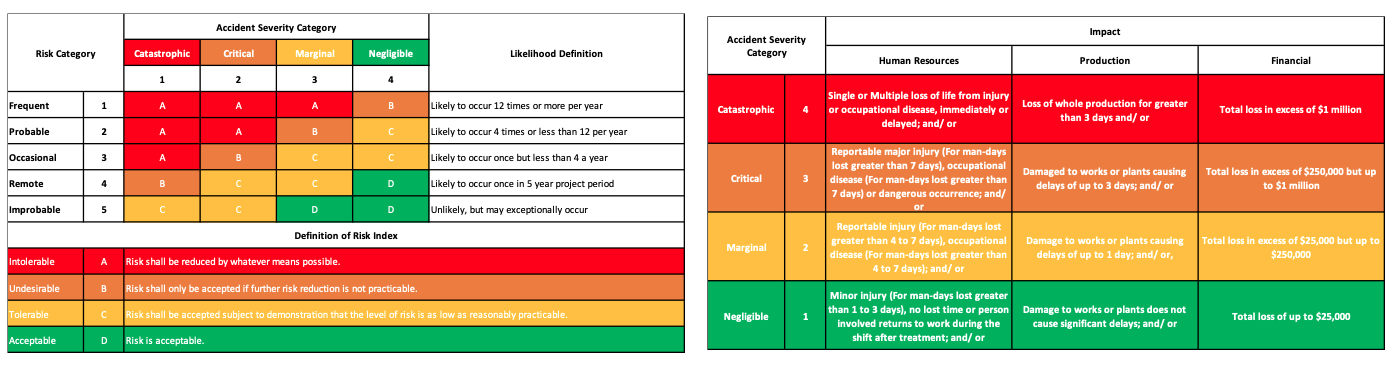

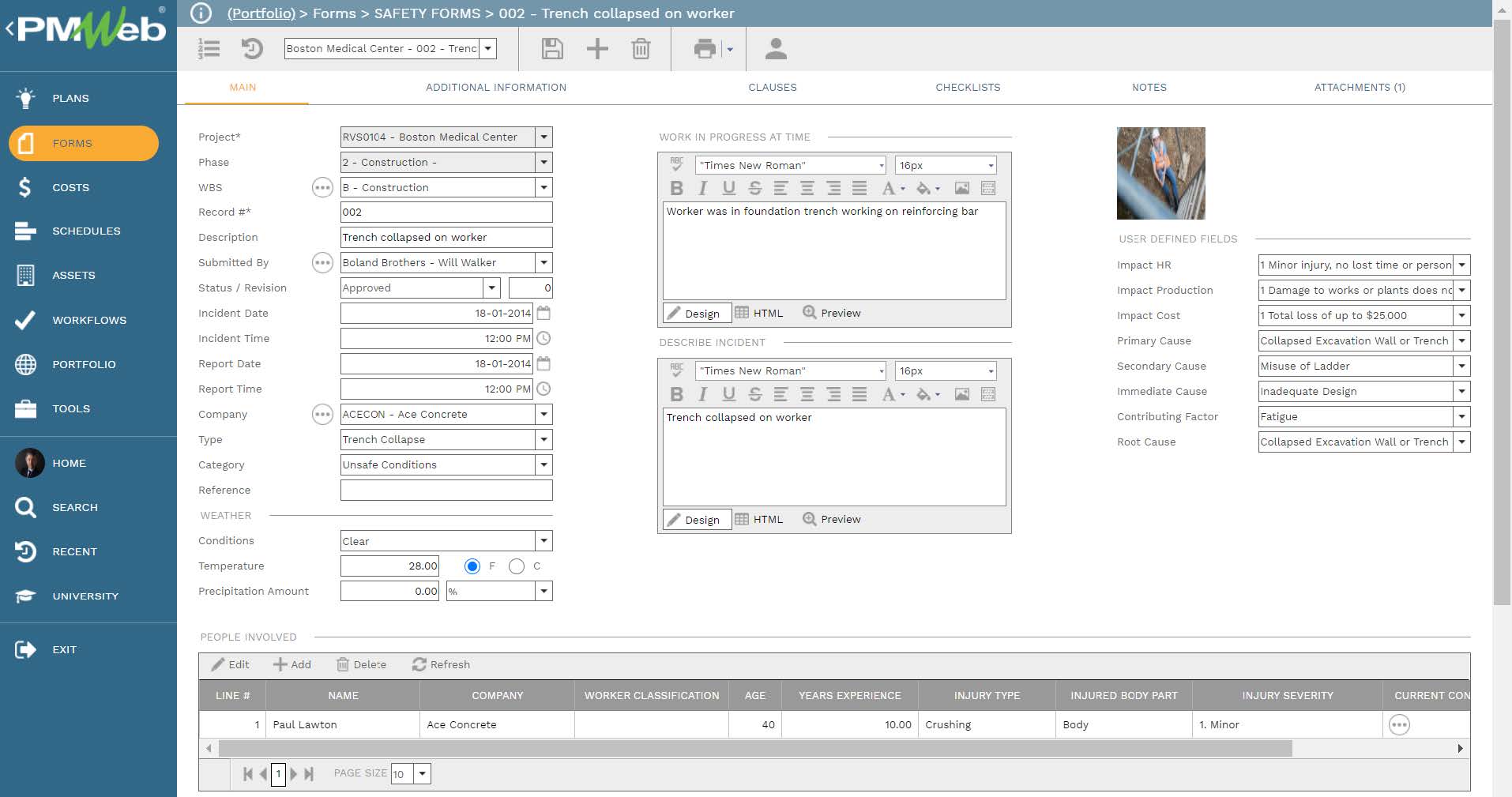

Using a Project Management Information System (PMIS) like PMWeb, the safety incident business processes, as well as the HSE risk register process, will be both managed on the same platform. PMWeb safety incident module comes ready with most of the needed fields to align the captured safety incidents with the HSE risk register. In addition, the form will be appended with three new fields with a predefined list of values for assessing the safety incident impact on human resources, work on-site and cost implications. Each field will have four predefined values that are aligned with the Accident Severity Categories being 4 Catastrophic, 3 Critical, 2 Marginal, and 1 Negligible.

In addition, the form will be appended with five fields for reporting the causes of the safety incidents. Those will be the fields for the primary cause, secondary cause, immediate cause, and contributing factors. The fifth cause, the root cause, will be completed by the safety manager to associate the safety incident with the HSE risk that will result from this cause. Those five causes will have the same predefined list of all causes that will be standard for all projects managed by the organization.

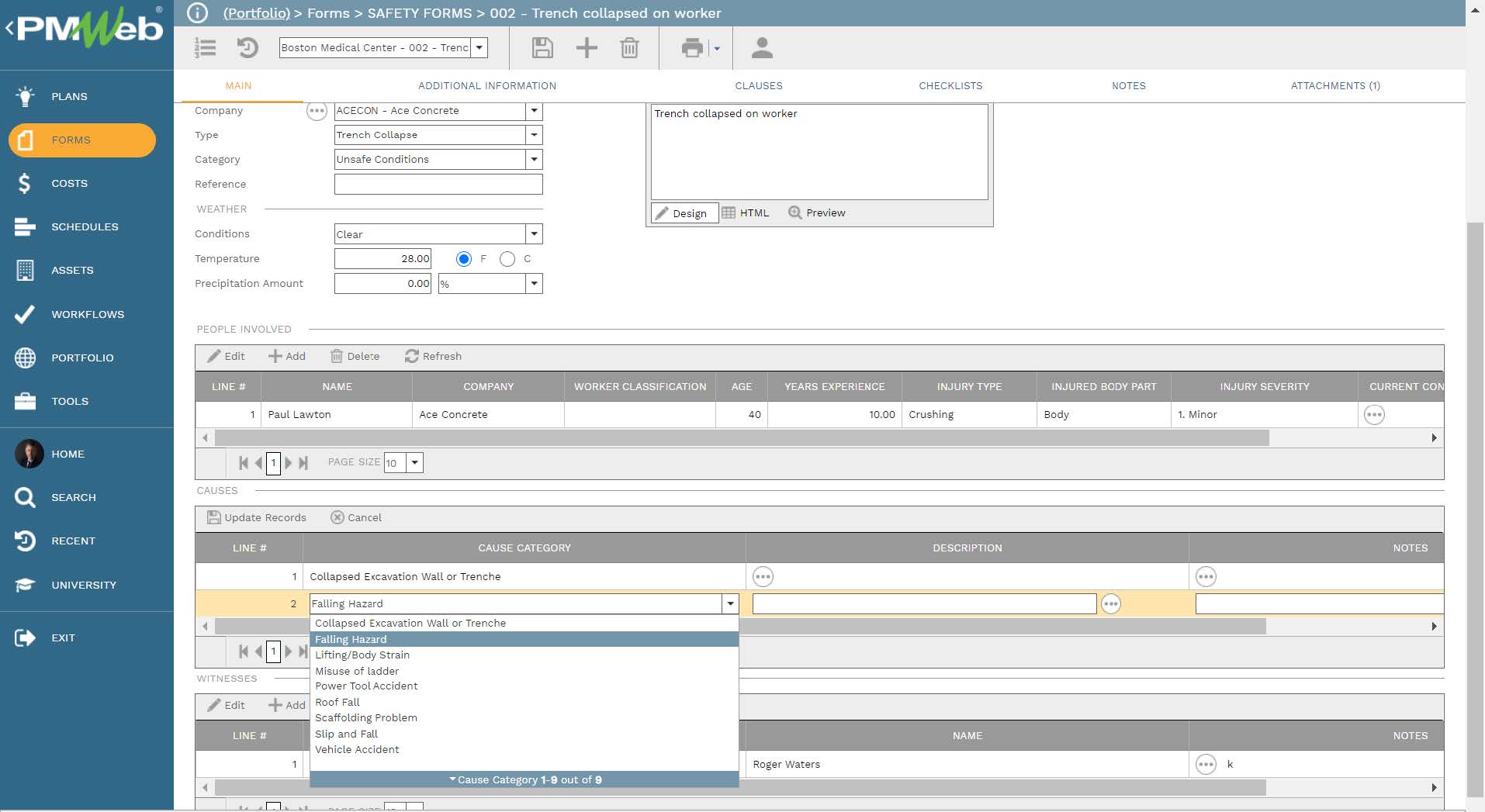

The list of predefined safety incident causes, which should be always updated with new causes, could include for example Vehicle Incident, Slip and Fall, Misuse of Ladder, Falling Hazard, Roof Fall, Scaffolding Problem, Power Tool Accident, Lifting/Body Strain, Collapsed Excavation Wall or Trench, Improper/Inadequate Training, Improper PPE, Eyes not on Task, Inadequate Design, Ergonomics, Rushing, Poor Lighting, Workstation Design, Fatigue, Incorrect Mapping, Unsafe Action, Slipped/Broken/Worn Tool, Mechanical Failure, Management System- Lack of Process, Materials – Wrong Type for Job, Machine/Equipment – Incorrect Tool Select, Complacency, Materials- Defective Raw Materials, Covid-19 and Others. It is of great importance that the predefined list of causes is appended with newly emerging causes.

It is recommended that for each one of those reported causes, details be captured in the causes section of the safety incident form. For each reported cause, PMWeb allows adding the description and notes. This section also enables adding other causes in addition to the five causes categories that have contributed to the occurred safety incident. The provided description and notes for each reported cause are of great importance when analyzing the causes and impacts associated with the reported safety incident.

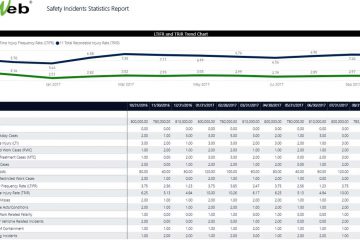

By having the details of the causes and effects or impacts captured in the safety incident form, the remaining parameter for the risk assessment will be to establish the likelihood of occurrence for each reported root cause. The safety incident date captured in the safety form will be the basis for determining the occurrence likelihood of the root cause or risk. There will be five likelihood categories; Frequent for Likely to occur 12 times or more per year, Probable for Likely to occur 4 times per year, Occasional for Likely to occur once a year, Remote for Likely to occur once in a 5-year project period, and Improbable for Unlikely, but may exceptionally occur.

The risk likelihood report will include histograms to display the count of the actual occurrences of each root cause or risk over 12 months. The report can be for a single project, program, portfolio of projects and programs, or the complete list of projects managed by the organization. The report will have four identical histogram visuals for which there will a histogram for the likelihood category being Frequent, Probable, Occasional, and Remote. The data for the Improbable category will not be reported on as any root cause or risk that it is the likelihood is not of the categories for Frequent, Probable, Occasional and Remote, then it will be presumed to have the category of Improbable.

The histogram bars will be color-coded per the Accident Severity Categories which are Catastrophic (Red), Critical (Orange), Marginal (Yellow), and Negligible (Green). The report will also include a table of all safety incidents reported within the year of when those incidents have occurred. For each incident, the report will detail the incident description, occurrence date, root cause, reported by, accident severity category, primary cause, secondary cause, immediate cause, and contributing factor.