No one can deny the high cost, delays and wasted effort of rework for poor quality of work. This is especially true when the rework involves reinforced concrete structures where the cost, time and effort needed to demolish and remove poured concrete could be enormous. Therefore, having a detailed checklist of all that needs to be inspected before the placing of the concrete, while placing the concrete and after placing the concrete will assure the quality of poured concrete and reduce the risk of having low-quality concrete.

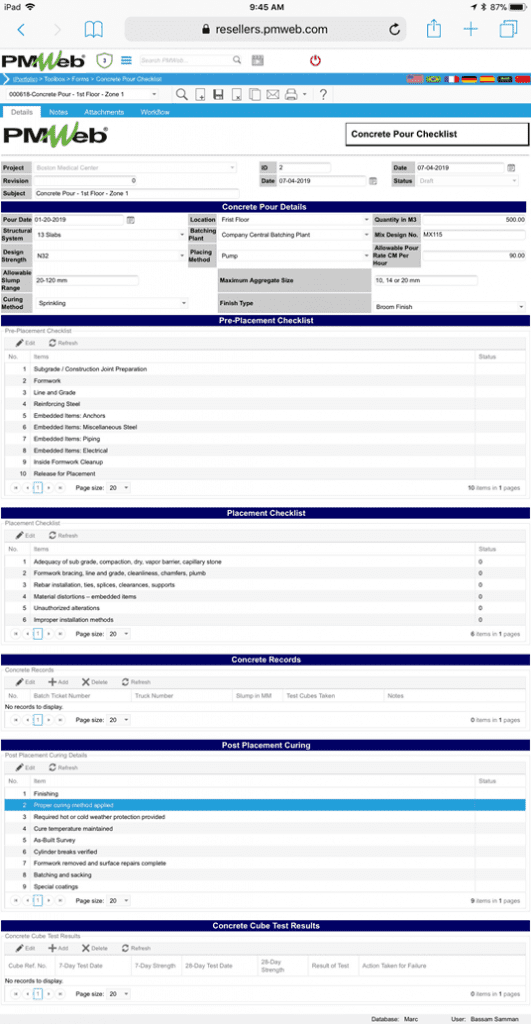

Using a Project Management Information System (PMIS) like PMWeb, the project’s quality management team can create the quality assurance/ quality control checklists for the different material items to be permanently incorporated in the project. One of those checklists is the Concrete Pour Checklist. Using PMWeb Custom Form Builder, a form will be created to capture the details of all items to be inspected and verified. The form will have details of the unique record number, subject, project and workflow status including the project team member who created the form.

The Concrete Pour Checklist header will also include details on pour date, location, quantity in M3, structural system, location and time of batching, mix design number, allowable slump range, design strength, maximum aggregate size, placing method, allowable pour rate, curing method and type of finish. The header could include other information that the quality management team might find it necessary to have.

In addition, the Concrete Pour Checklist will have five tables. The first table is for items to be inspected prior to placing the concrete which can be titled “Pre-Placement” while the second table will be for the items to be inspected during the concrete and titled “Placement”. The two tables will have pre-defined items to be inspected.

The third table will be titled “Concrete Records” which will be used to capture the details of transit mixer trucks that have delivered the poured concrete. The table will include details of the slump test as well as whether test cubes were taken or not. The fourth table will be for items to be inspected after completing the concrete pour which will be titled “Post Placement Curing” which will also have predefined checklist items. The last table will be titled “Concrete Cube Test Results” will be used to capture the details of the cube test results taken during the concrete pour. The reason for having multiple tables is to enable assigning different responsibility for verifying the checklist items assigned to each table.

Since PMWeb is a zero-foot print application, the Concrete Pour Checklist can be accessed using any browser or any mobile device such as iPad among others. PMWeb is also responsive design enabled so the form will fit automatically on the displayed screen. Using the form on a mobile device also allows the user to take and attach pictures and videos as well as use the “Speech-to-Text” option to fill the text fields of the form.

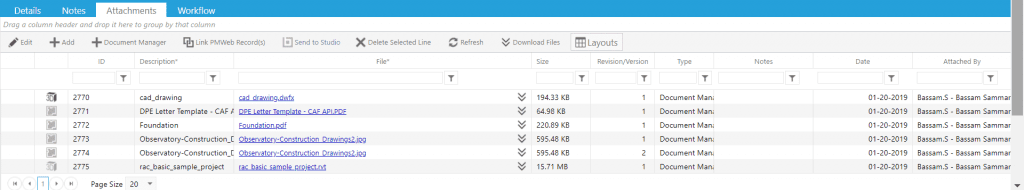

The attachment tab will be used to upload and attach copies of the different concrete slump tests and other tests as well as copies of batch ticket numbers. In addition, pictures taken of the concrete pour will be also uploaded and attached.

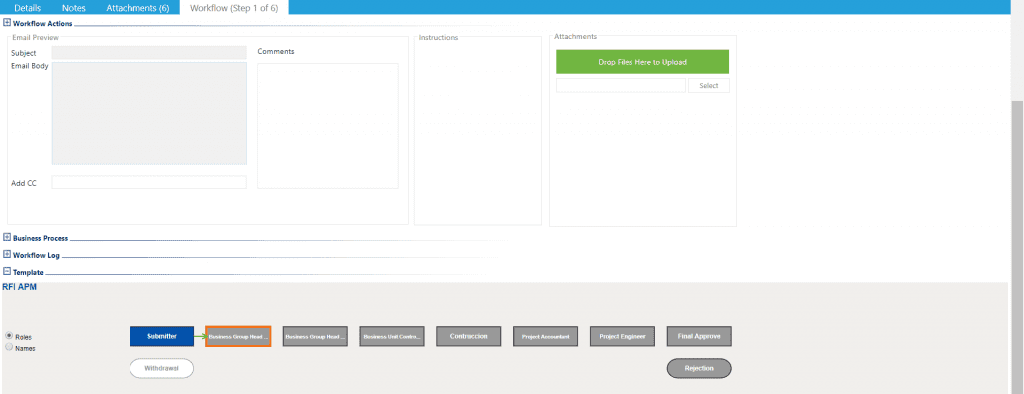

The workflow assigned to the Concrete Pour Checklist will be used to distribute the checklist to the intended recipients. The workflow will be aligned with the access rights set for each table of the five tables that the form has. The form will be initiated by the contractor and then the predefined workflow will distribute the Concrete Pour Checklist form to all designated project team members.

Using PMWeb BI Report Writer, the quality management team can design the Concrete Pour Checklist output form in the desired format. The output form will be needed to be formally signed and sometimes even stamped. The form layout will group the checklist items for each one of the five tables included in the custom form.

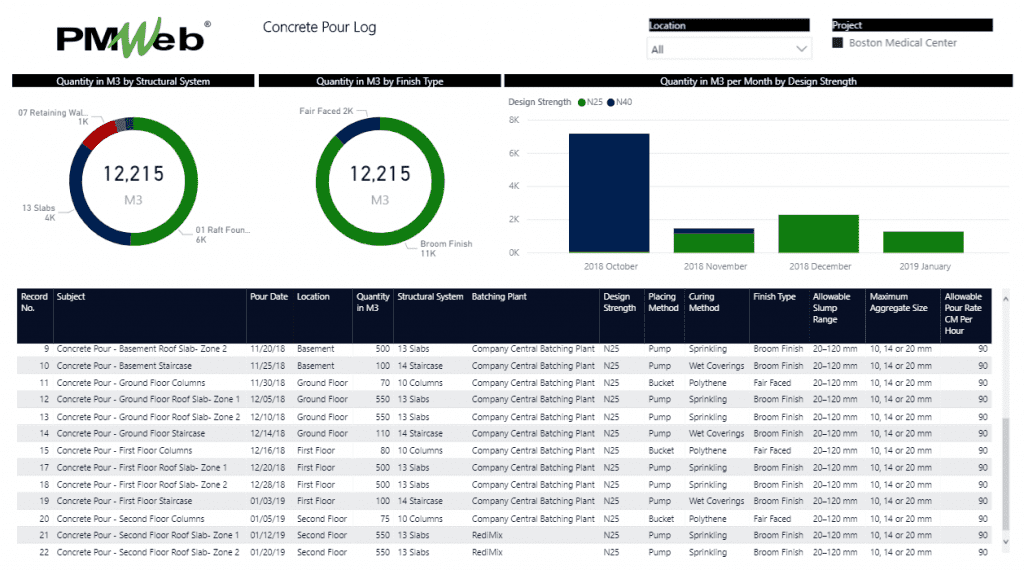

PMWeb BI Report Writer will be also used to create the Concrete Pour list which will detail all concrete pours that took place during the project duration. The report format and layout can be designed to meet the project quality management team requirements, but it could include a log of all concrete pours with visuals to summarize the poured concrete quantities by structural system, location, finish type, period, among many others.