One of the major dilemmas that face contractors on construction sites is how to reduce material waste such as steel reinforcement, cement, blocks, premix mortar, ceramic tiles, pipes and wires, and wood panels damaged or unused for various reasons during construction. It is estimated that this can be as high as 10 to 15% of the materials that go into a building, a much higher percentage than the 2.5-5% usually assumed by quantity surveyors and estimating engineers while preparing the bid proposal.

To be able to implement actions that could reduce if not prevent material wastage on construction sites, contractors need to implement measures to identify, quantify, monitor, evaluate and report on what is causing material wastage. Those actions would become the business strategy that contractors can adopt and implement across their construction sites.

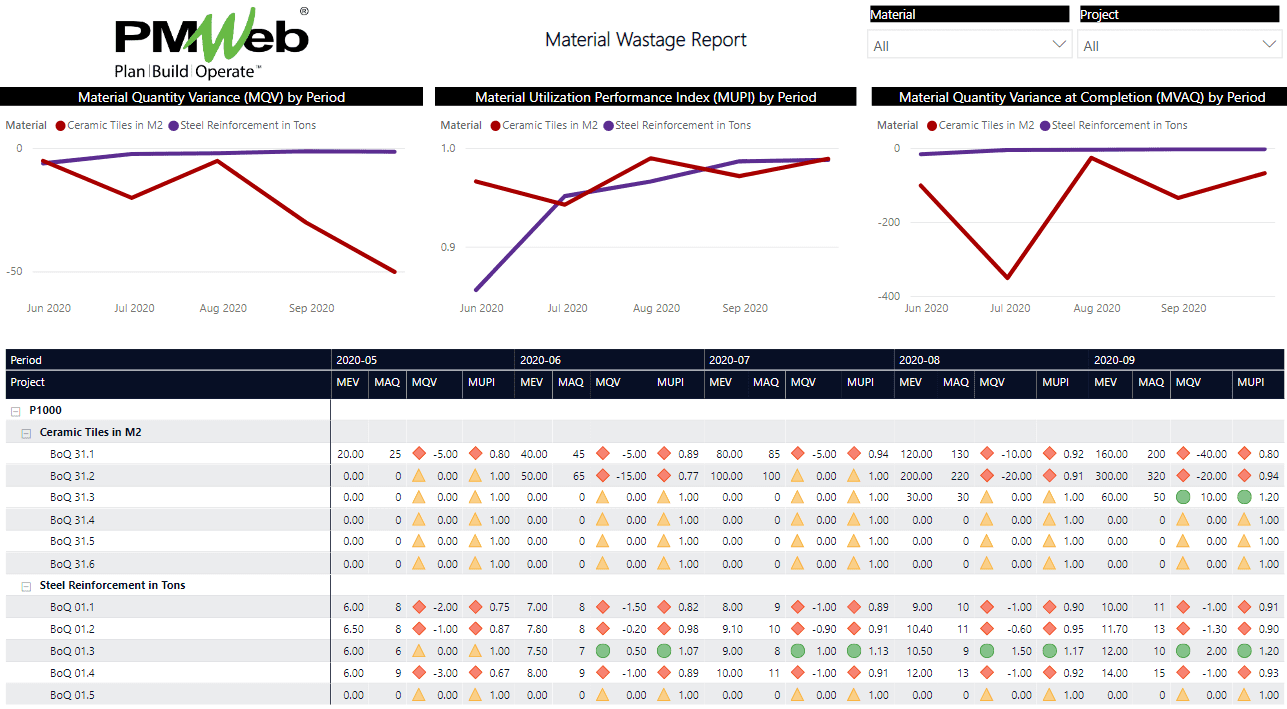

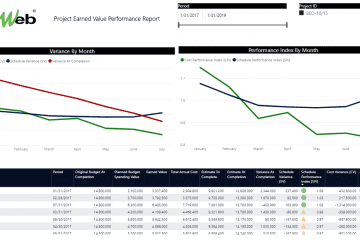

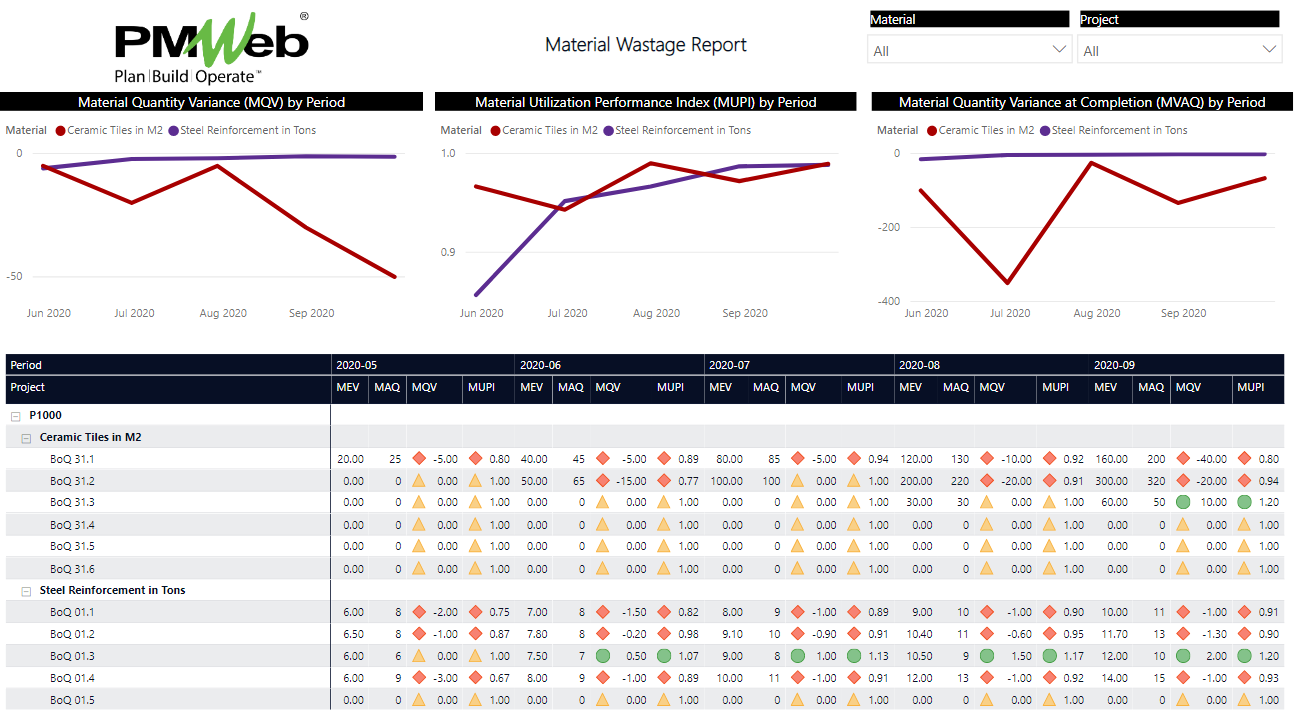

Using the Earned Value Management (EVM) principles, contractors could come with a solution to identify, quantify, monitor, evaluate and report on the causes of material wastage as well as assess the benefits and cost savings from implemented material waste prevention actions. The EVM principles will be used to quantify and calculate the values and measures for Material Budget at Completion (MBAC), Material Earned Value (MEV), Material Actual Quantity (MAQ), Material Quantity Variance (MQV), Material Utilization Performance Index (MUPI), Material Estimate to Complete (METC), Adjusted Material Estimate to Complete (AMETC), Material Estimate at Completion (MEAC) and Material Variance At Completion (MVAQ).

The proposed EVM solution will use the material quantity estimate for the Bill of Quantity (BoQ) items in the bid proposal as the planned material budget at completion (MBAC). It should be noted that the estimated material quantity will include the wastage percentage assumed by the quantity surveyors and estimating engineers. This will enable calculating the Material Earned Value (MEV) at the end of each progress period by multiplying the approved percent complete for each Bill of Quantity (BoQ) item by the material quantity estimate for the same item.

All ordered materials to be used on the project will be captured in purchase orders which can be issued to the supplier or the contractor’s own purchasing department. The quantities for ordered material in each purchase order need to broken down to their planned use as detailed in the Bill of Quantity. This will ensure the first step for preventing material waste by confirming that was has been ordered is in line with what was included in the bid proposal. All released material to the construction site will be recorded in the interim progress invoice issued against the relevant purchase order. This will be the Material Actual Quantity (MAQ) used.

This material progress information will enable the contractor to have the needed measures to identify, quantify, monitor, evaluate, and report on what is causing material wastage. The first measure will be the Material Quantity Variance (MQV) which is the difference between the Material Earned Value (MEV) and Material Actual Quantity (MAQ). A negative MQV value will indicate that material wastage has exceeded what was planned for. The second measure will be the Material Utilization Performance Index (MUPI) which will be calculated by dividing the Material Earned Value (MEV) by the Material Actual Quantity (MAQ). A MUPI value that is less than 1.00 will indicate that measures used to prevent material wastage are not effective.

For the contractor to envisage the magnitude of anticipated material wastage when the project comes to completion, the measure of Material Variance At Completion (MVAQ) needs to be calculated. This will require first to calculate the remaining estimated quantities for each material item (METC) which will equal to MBAC minus the MEV. To reflect the impact of the current Material Utilization Performance Index (MUPI) on the remaining estimated quantities for each material item, the METC will be divided by the MUPI value. The estimated material used when the project is completed (MEAC) will be the sum of MAQ and adjusted METC values. The MVAQ will be the difference between MBAC and MEAC. A negative value will reflect the anticipated increase of material wastage to what was originally estimated if no effective actions are implemented to stop the current wrong or ineffective practices that would lead to this increase.

Using a Project Management Information System (PMIS) like PMWeb, the process for identifying, quantifying, monitoring, evaluating, and reporting on what is causing material wastage can be one of the processes that can be implemented. By having a single platform like PMWeb to implement this process, contractors can be assured of a real-time single version of the true solution that is inline with the best practice of earned value management (EVM).

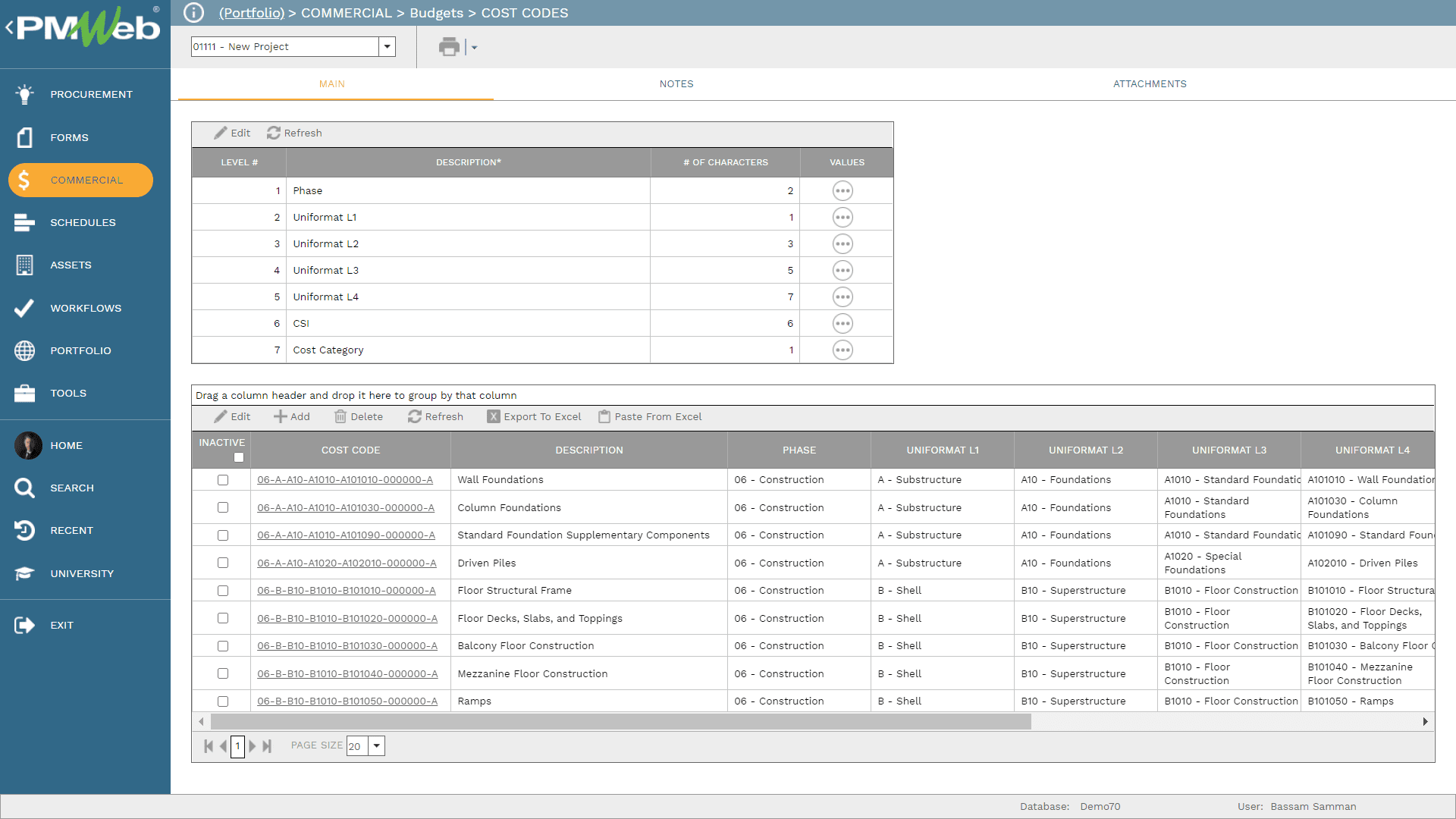

To start with, the cost breakdown structure (CBS) that will detail the desired control level needs to be created. The CBS will match the contract’s Bill of Quantity (BoQ) items. Usually, project owners and consultants will use one of the internationally recognized standards in providing the breakdown of the Bill of Quantity. One of those standards is the Construction Specification Institute (CSI) UniFormat.

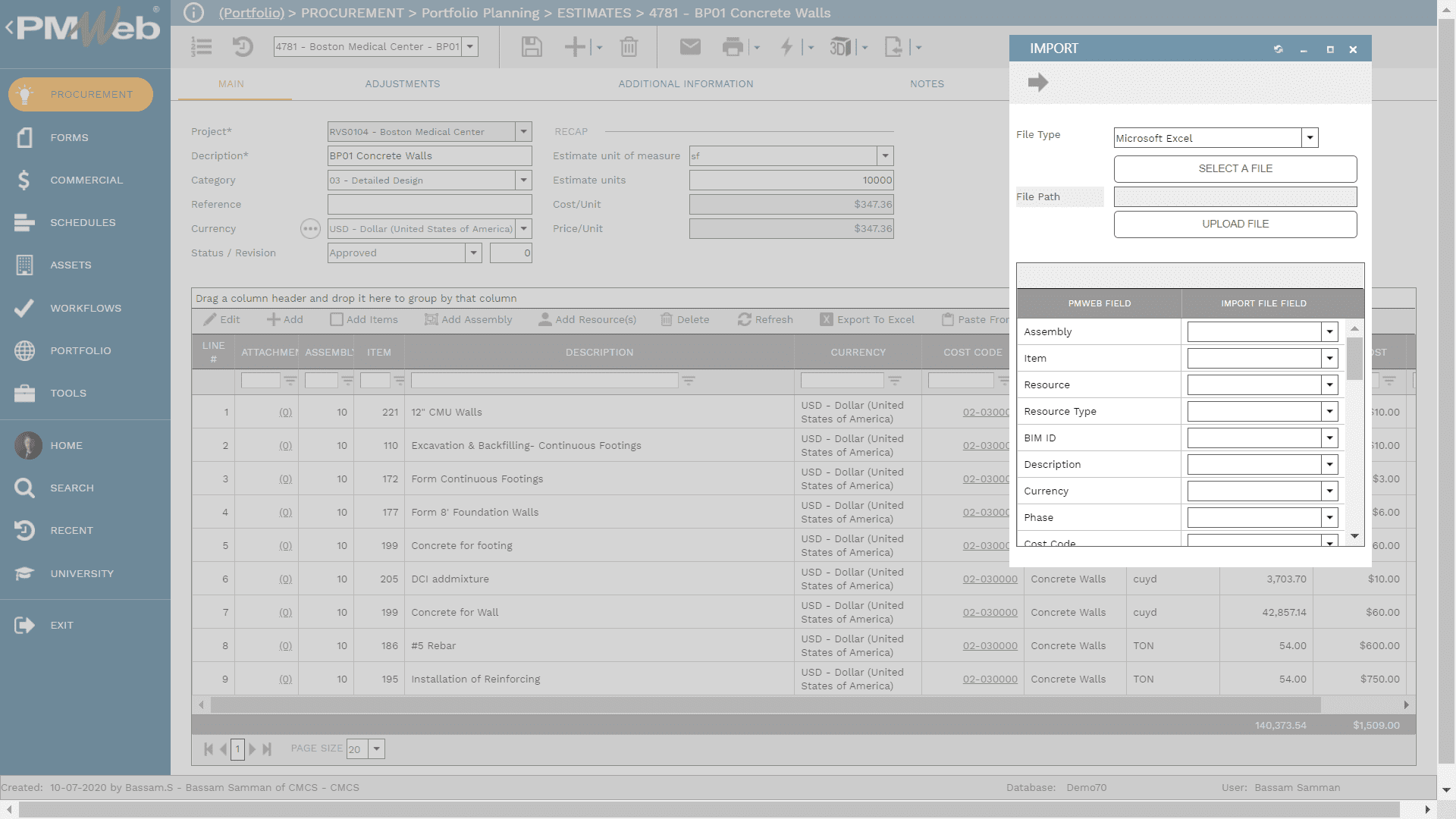

The next step will be to capture the estimated quantities for material items that were part of the approved cost estimate used in the awarded bid proposal. The material items need to be broken down to the level of the Bill of Quantity (BoQ) items level or any other selected control level as identified in the Cost Breakdown Structure (CBS). This will be achieved by using the PMWeb Estimate module for which the details of the estimated quantities for material items captured in a MS Excel file will be imported into PMWeb.

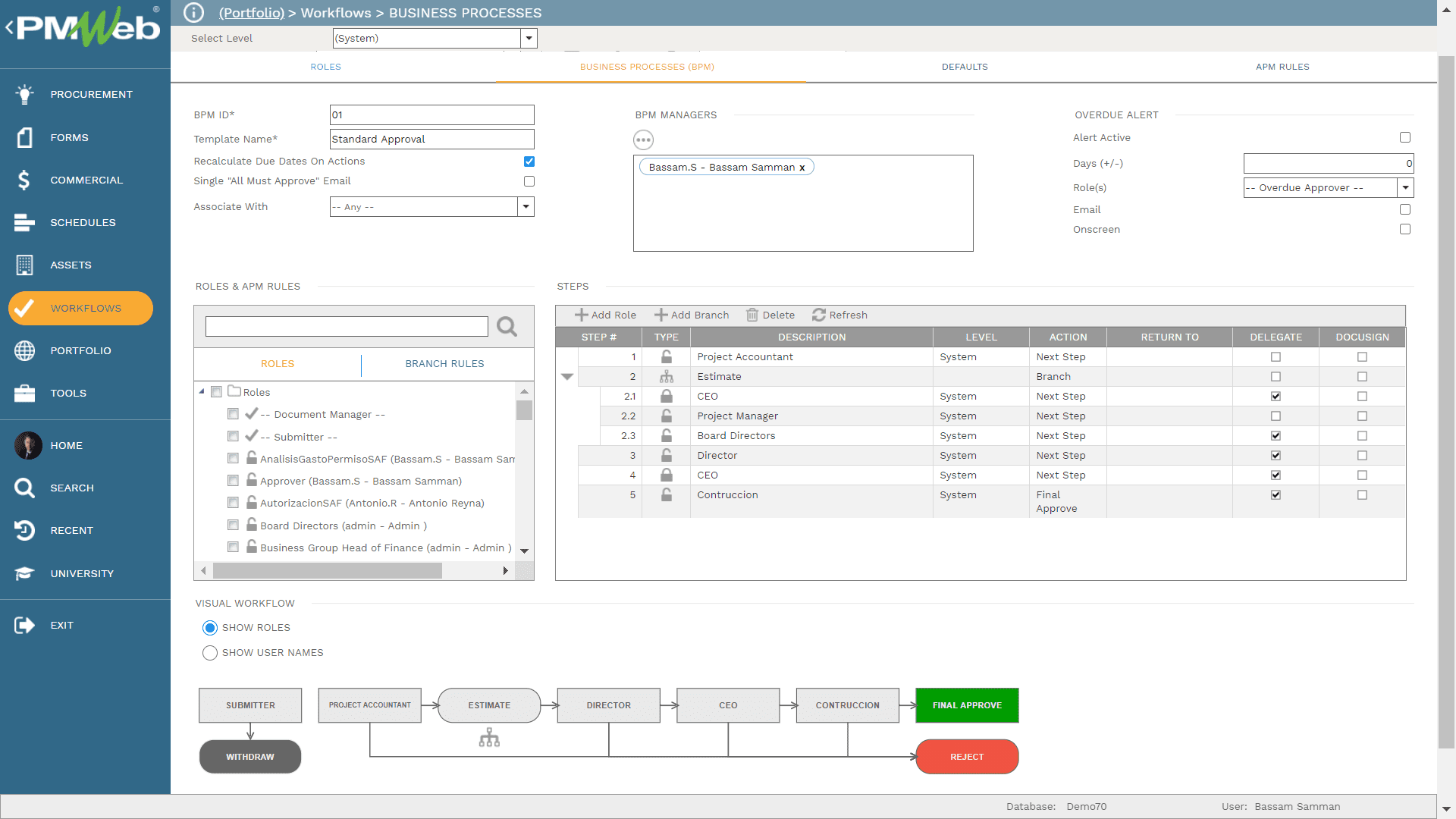

To ensure that the imported cost estimate is formally reviewed and approved by the construction project management team, quantity surveyors, and cost estimating team as well as other project stakeholders, it is highly recommended to assign a workflow to the cost estimate. The workflow will identify the sequence of tasks that are needed to submit, review, and approve the cost estimate. Those tasks will be assigned to their responsible project team members in accordance with the project’s responsibility assignment matrix (RAM) as well as the set authority approval levels.

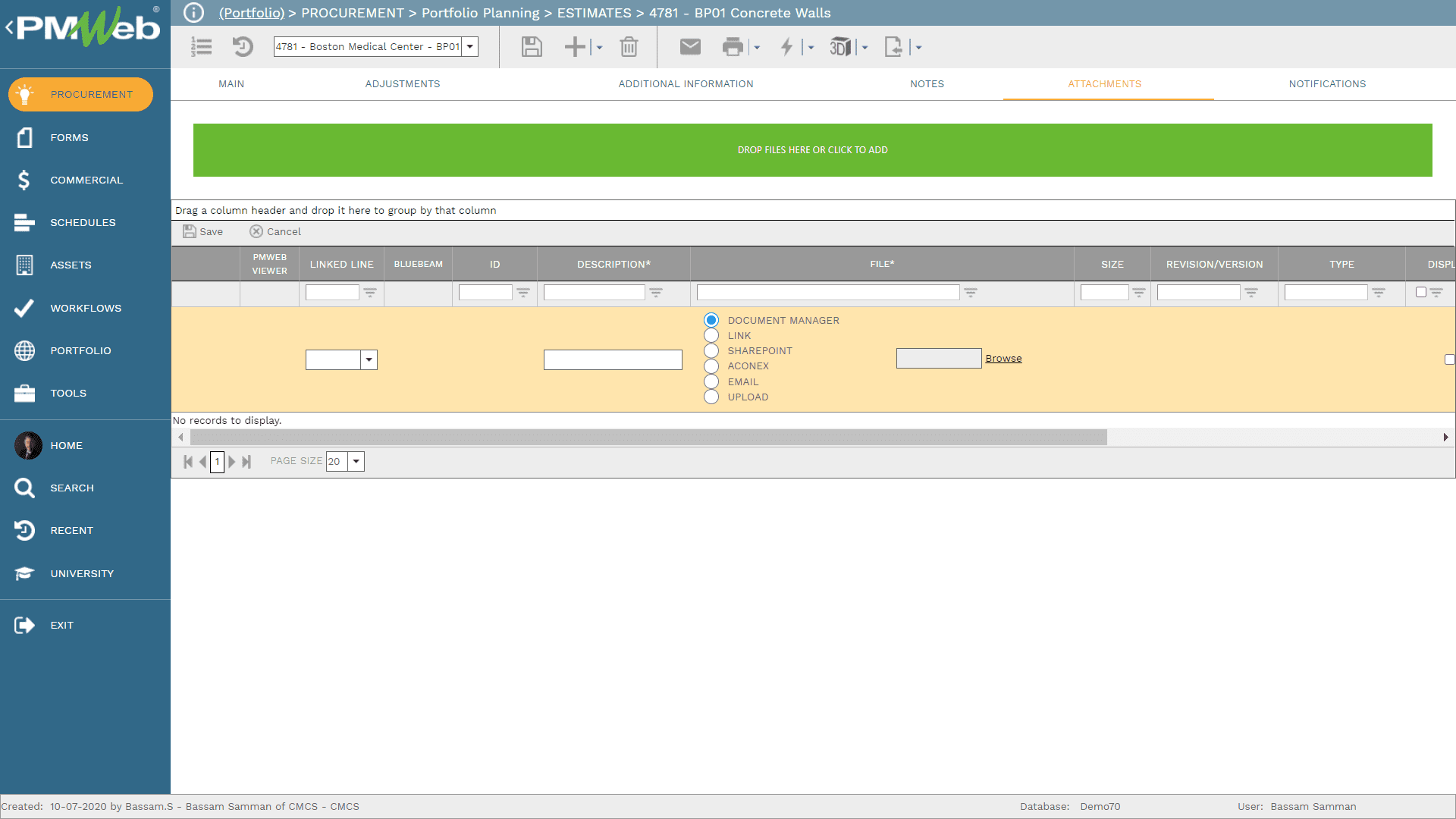

Of course, it is also recommended to attach all supportive documents that the quantity surveyors and cost estimating team have used to estimate the material usage on the project. The cost estimate attachment tab will be used to attach all supportive documents as well as link all relevant records and imported MS Outlook emails to the cost estimate. PMWeb document management repository will be used to create folders and subfolders for uploading and storing all documents associated with the cost estimate.

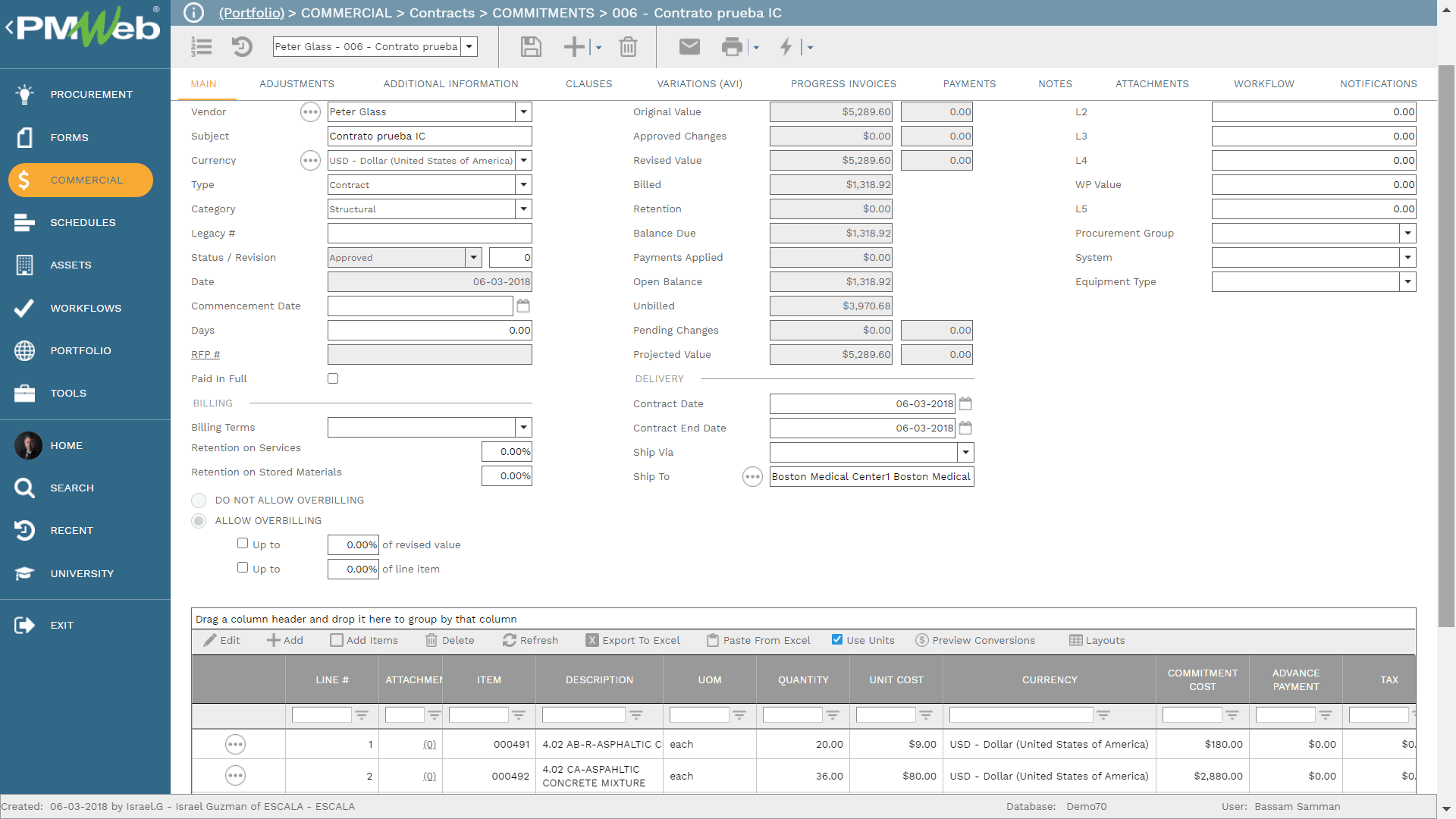

The approved material cost estimate will be used to create purchase orders or commitments for material usage. There is no limit to the number of purchase orders to be issued using PMWeb. This will enable having purchase orders for each vendor or supplier as well as internal purchase orders for the contractor’s purchasing department. This required if the contractor has a centralized process to manage all material purchases and release for all of their awarded contracts. All issued purchase orders will be automatically detailed to the level of the Bill of Quantity (BoQ) items level or any other selected control level as identified in the Cost Breakdown Structure (CBS) used in the cost estimate module.

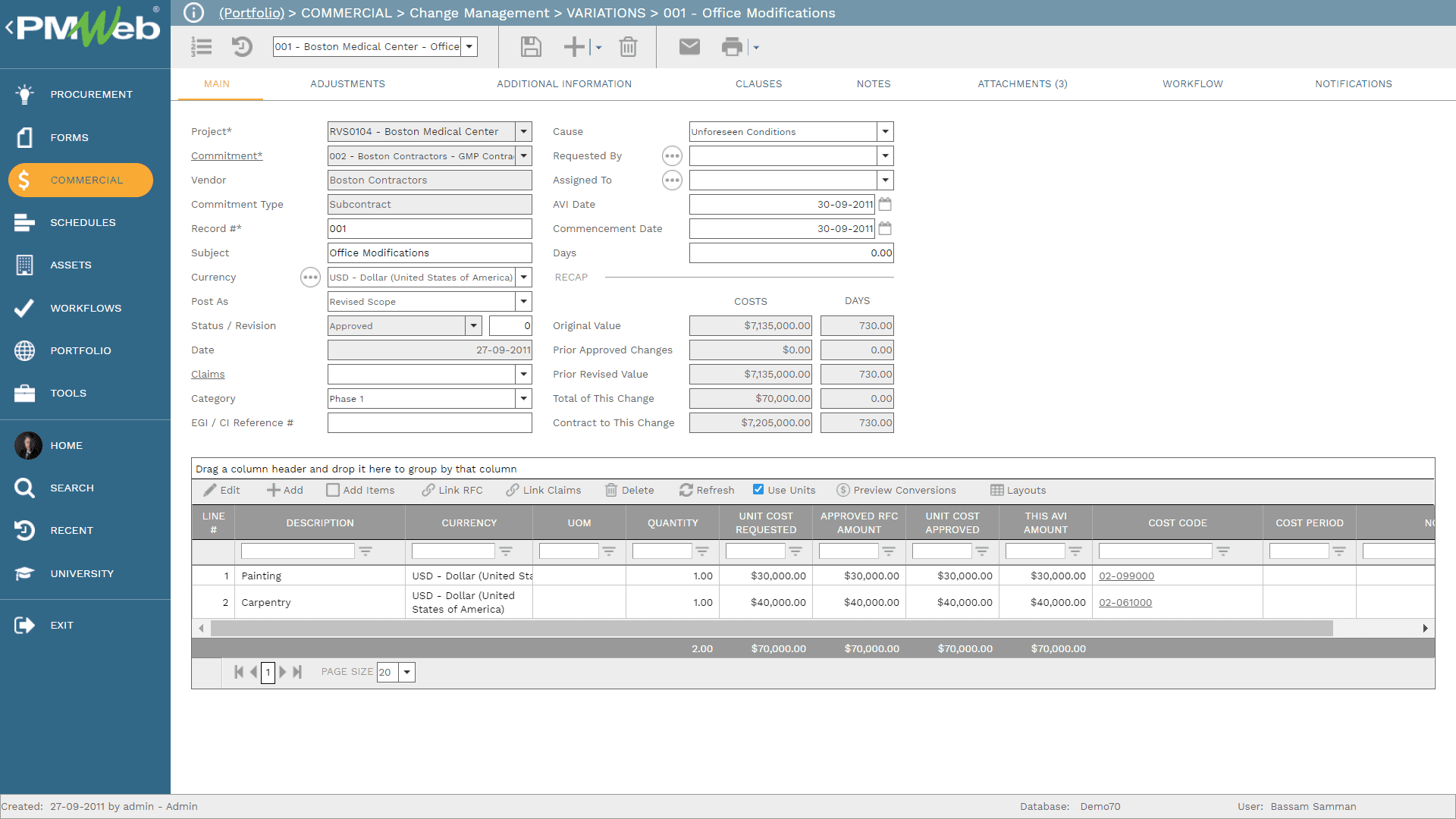

To ensure that all changes to the estimated material quantities resulting from approved change orders issued to the Contractor against the originally awarded contract are captured, the PMWeb Change Order module will be used to keep those estimated quantities current. Similar to the cost estimate module, a workflow can be assigned to the purchase order as well as change order modules to document the review and approval of all those commitments. In addition, supportive documents can be attached, and relevant records can be attached to each purchase order.

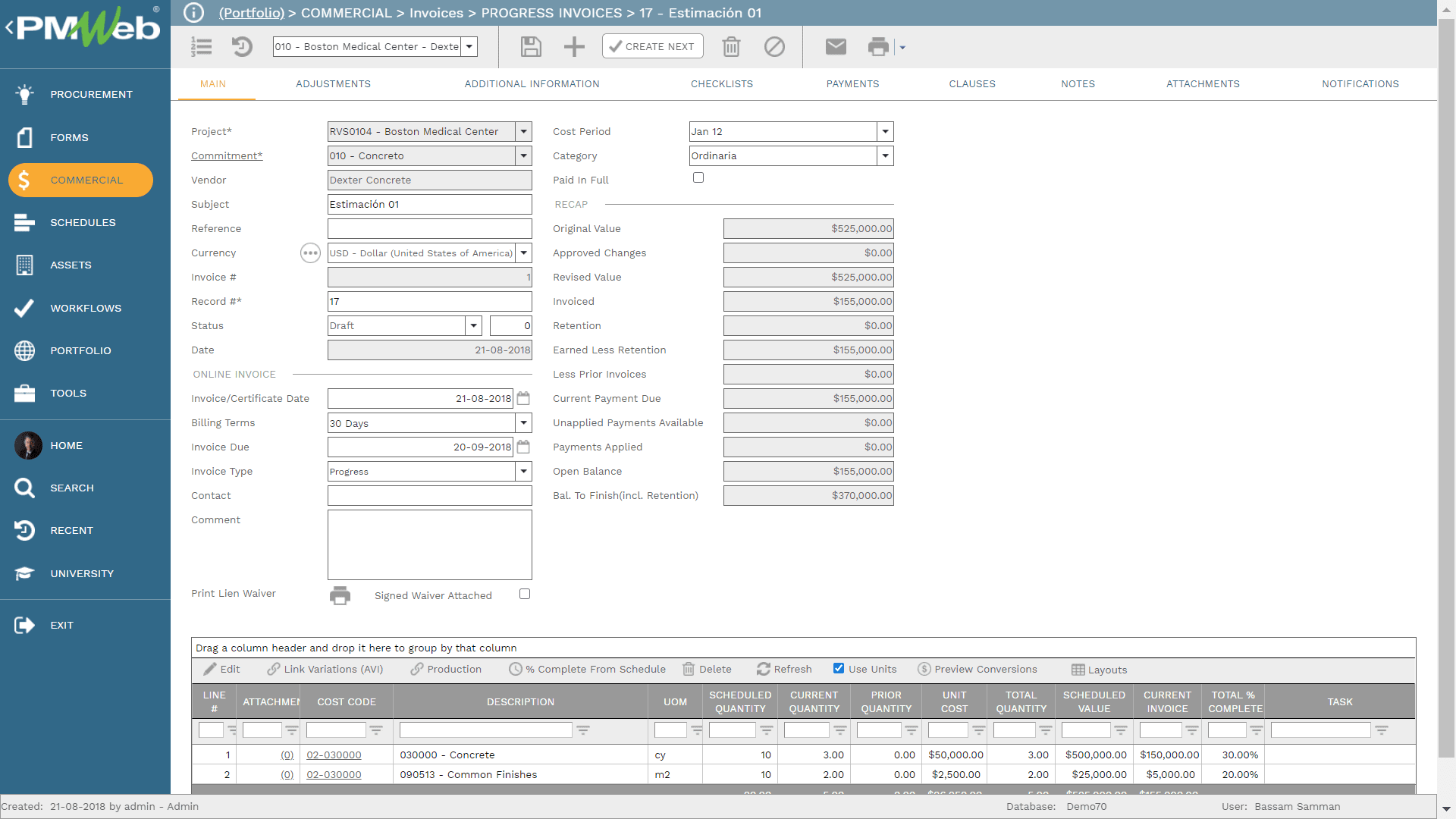

As the project progresses, the PMWeb progress invoice module will be used to capture the values of Material Actual Quantity (MAQ) consumed to date and the percent complete for each Bill of Quantity (BoQ). The percent complete value will be used to calculate the Material Earned Value (MEV) by multiplying the percent complete value with the total quantity for the relevant BoQ item which is also known as Material Budget at Completion (MBAC). To be able to achieve, a new user-defined field will be created in the progress invoice to capture the earned percent complete for each bill of quantity (BoQ) item.

The three values of MBAC, MAQ, and MEV will be the values needed to calculate the other values for Material Quantity Variance (MQV), Material Utilization Performance Index (MUPI), Material Estimate to Complete (METC), Material Estimate at Completion (MEAC) and Material Variance At Completion (MVAQ). Those values will be used to identify, quantify, monitor, evaluate, and report on what is causing material wastage on the construction site. This enables the Contractor management and site management team to identify and implement actions to stop material wastage and monitor the effectiveness of those actions.

The Material Wastage Report shown below provides three visuals to report on the for Material Quantity Variance (MQV), Material Utilization Performance Index (MUPI), and Material Variance At Completion (MVAQ). Each material will have its own curve. The report will also include a matrix report to provide the details of Material Earned Value (MEV), Material Actual Quantity (MAQ), Material Quantity Variance (MQV), and Material Utilization Performance Index (MUPI) for each period. The report will include filters to select what material to report on as well as which project to report on.