Another quality control process that needs to be monitored, evaluated, and reported in the project control system (PCS) is the Static and RotatingEquipment Inspection Checklists. For oil and gas projects, static equipment comprises valves, boilers, furnaces, and heat exchangers. Oil and gas rotating equipment comprise turbines, pumps, and compressors. On the other hand, static equipment is with no moving parts is comparatively morereliable.

Similar to the other quality control processes, the difference between a project control system (PCS) that is managed by the project owner or the contractor is the ownership of the data captured in the static and rotating inspection reports. Regardless of who is managing the PCS, the inspection forms is available to all entities who need to have this information.

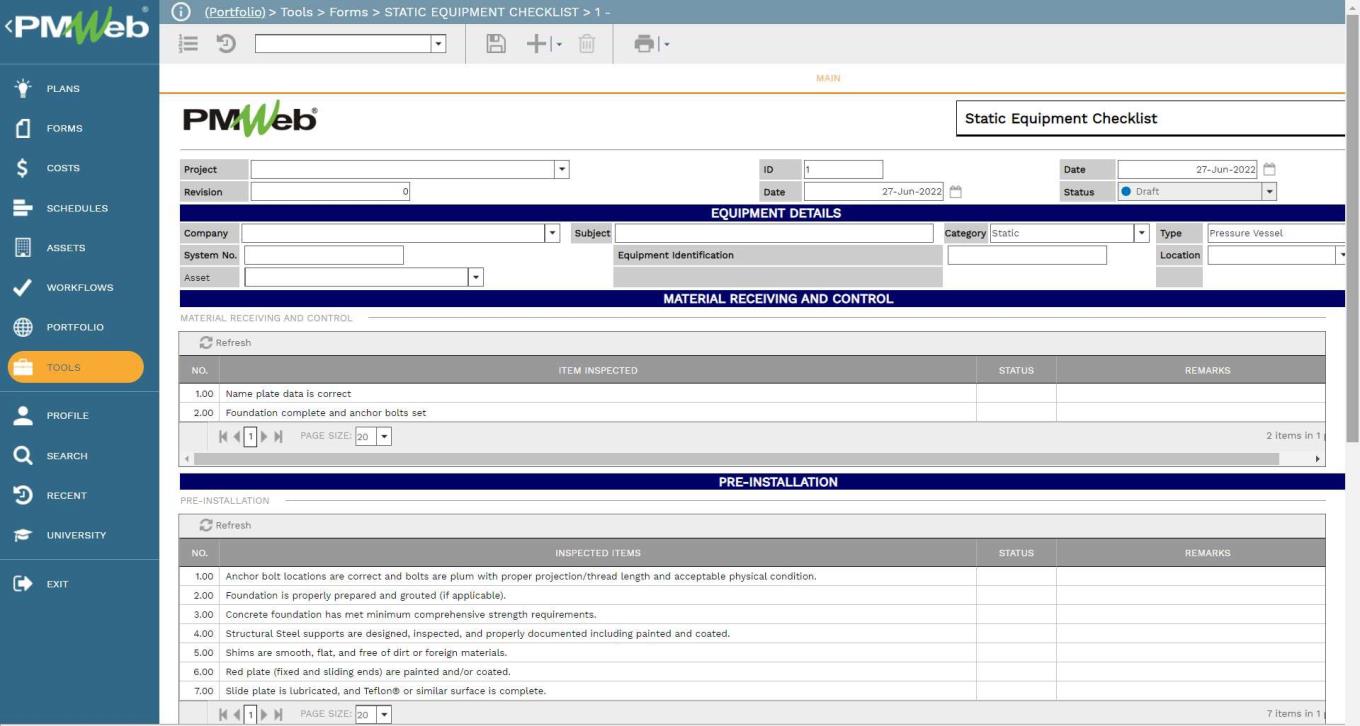

The Static and Rotating Equipment Inspection Checklists which gets created using the PMWeb visual custom form builder are another example of aquality control-related business process that can be managed using PMWeb. The templates will be designed to capture the data relevant for a static or rotating equipment inspection that might be done on the project. This is needed to ensure that all items to be inspected are included in the checklist. These lists includes tables with items to be inspected related to Material Receiving and Control, Pre-Installation, and Installation.

Delivery notes, installation manuals for equipment, installation shop drawings, pictures of the equipment location before and after installation, and other particulars of the inspected equipment will be uploaded and attached to their relevant inspection. A workflow will be added to the static and rotating equipment inspection checklists to ensure the complete review of items included in each table in the checklist and formalize the finalapproval of the equipment inspection.

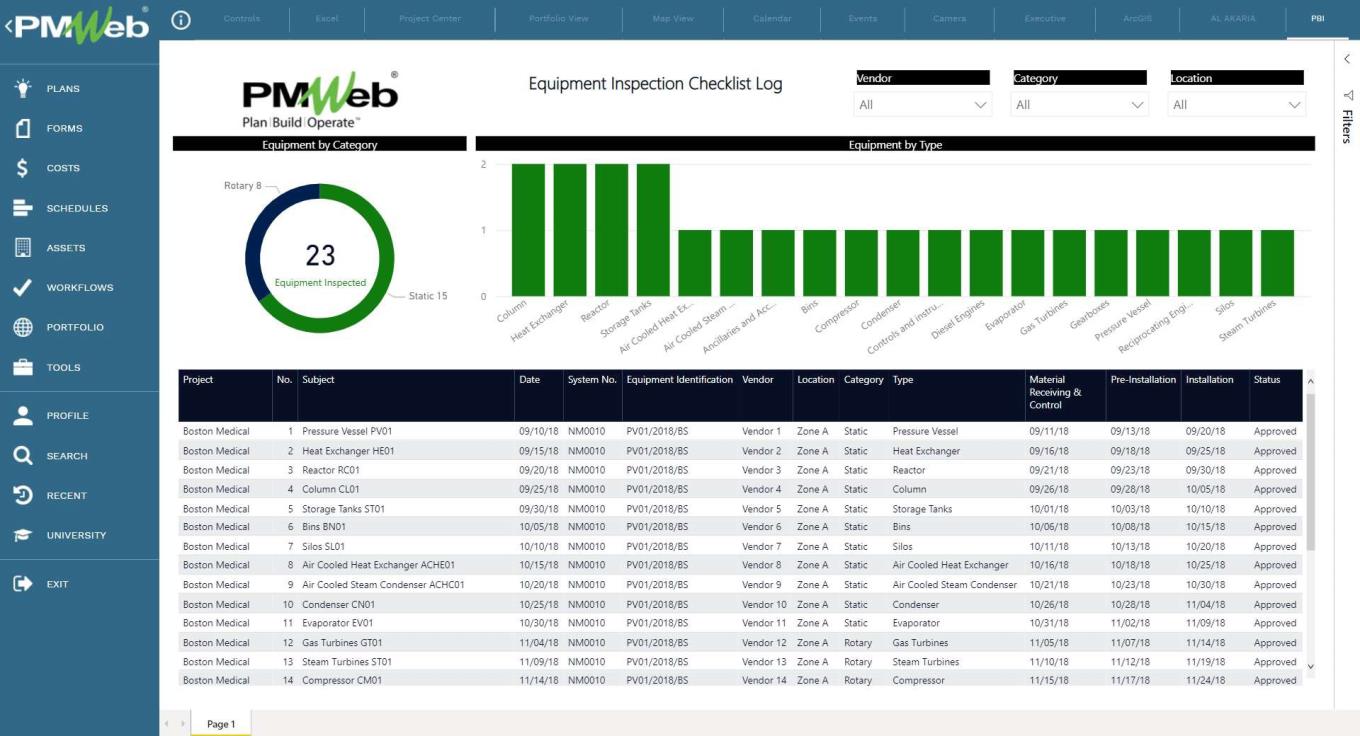

The equipment inspection checklist report captures the details of all inspections carried out for static and rotary equipment. The tabular section captures details of the equipment and actual approval dates for material receiving and control, pre- installation, and installation. Visuals show thequantity of inspected equipment by category as a donut chart and type as a histogram.

Reference

The content of this article was extracted from the book titled “Let’s Transform: Enabling Digital Transformation of Capital Construction ProjectsUsing the PMWeb Project Management Information System – 2nd Edition” written Bassam Samman.

The book provides project owners with oversight on how technology available today can support their efforts to digitally transform the management of their projects’ portfolios. For each capital project life cycle stage, PMWeb is used to detail how the relevant project management business processes can be digitalized to enforce transparency and accountability in delivering projects. In addition, MS Power BI was used to show how the real-time, trustworthy data captured in PMWeb can be aggregated, modeled, monitored, evaluated, analyzed, and reported at anytime,anywhere using any device.