For all capital construction project owners, having their completed facilities running without defects or issues is what matters most for them. Failures associated with electro-mechanical and other types of services systems result in unhappy occupants and users of those facilities and negatively impact their value. Unlike other types of building systems where they are exposed and can be visualized, most of the electro-mechanical and other types of services systems’ components are hidden or covered. For example, electrical conduits and wiring, HVAC ductwork and piping, water supply piping, drainage piping, telecommunication conduits, and wiring, fire protection piping, fire alarm conduits, and wiring, and others.

The failure to execute a project to what it had been designed and specified for is usually the main reason for those failures. Treating the high exposure risk of poor quality requires implementing a number of quality assurance and quality control business processes. One of those business processes is the Work Inspection Request (WIR).

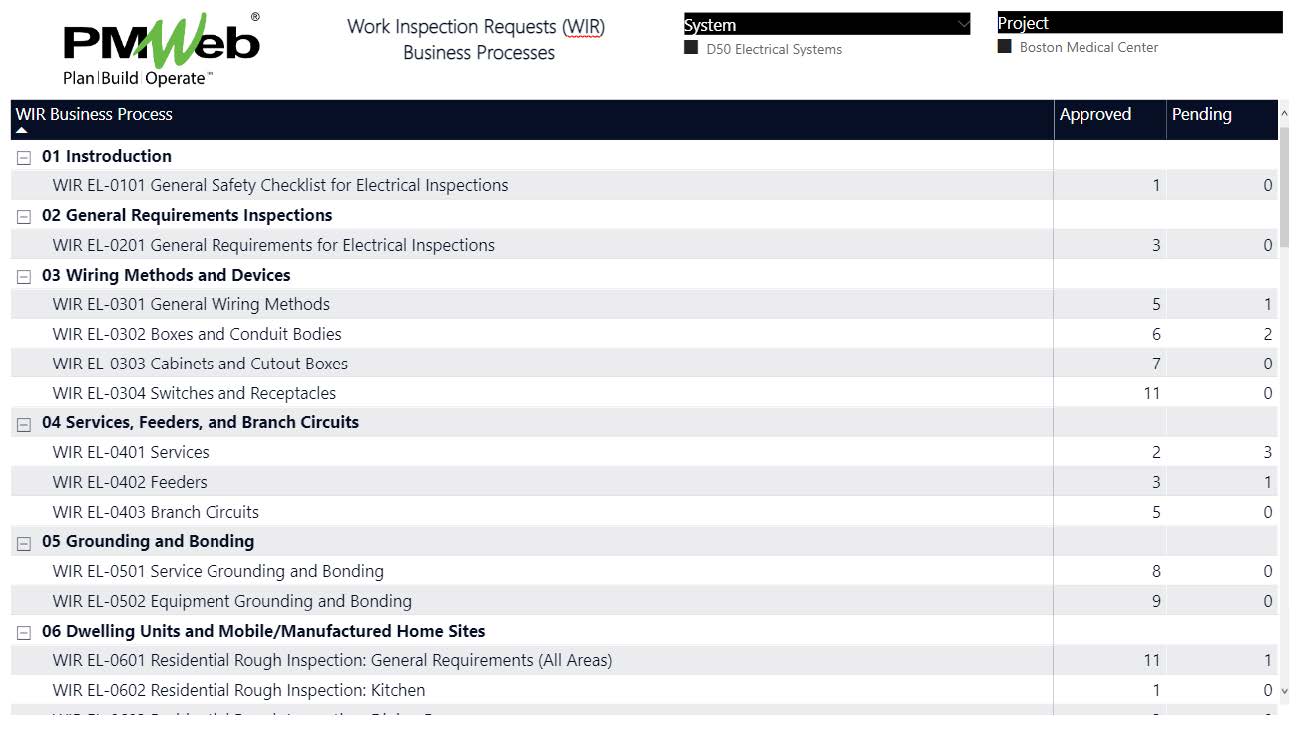

Although, every capital construction project has the Work Inspection Request (WIR) as one of the standard business processes, nevertheless, they tend to be generic and not specific to the building system and the components of those systems to be inspected. For example, the Electrical Inspection Manual, 2014 Edition by Noel Williams; Jeffrey S. Sargent; Jones & Bartlett Learning, has identified 77 electrical inspection checklists that could be used on capital construction projects to ensure compliance with the National Electrical Code® (NEC) rules (www.jblearning.com/catalog/productdetails/9781284041835).

The NEC is the most widely adopted codes in the world and it is the most complete set of electrical code requirements that govern electrical installations in the interest of safety for persons and property and results in electrical installations and systems that are essentially free from hazards. The NEC is the minimum set of electrical rules that must be followed for compliance and assurances that occupancies are safe from potential electrical hazards (www.neca-neis.org/safety-and-the-nec).Using a Project Management Information System (PMIS) like PMWeb, templates for all types and categories of Work Inspection Request (WIR) for all building systems can be created. Those templates not only ensure that all completed work on site has been done, inspected, and approved in accordance with what had been specified, but also enable capturing, documenting and using the massive knowledge associated with those inspections across the complete projects’ portfolio that the project owner has.

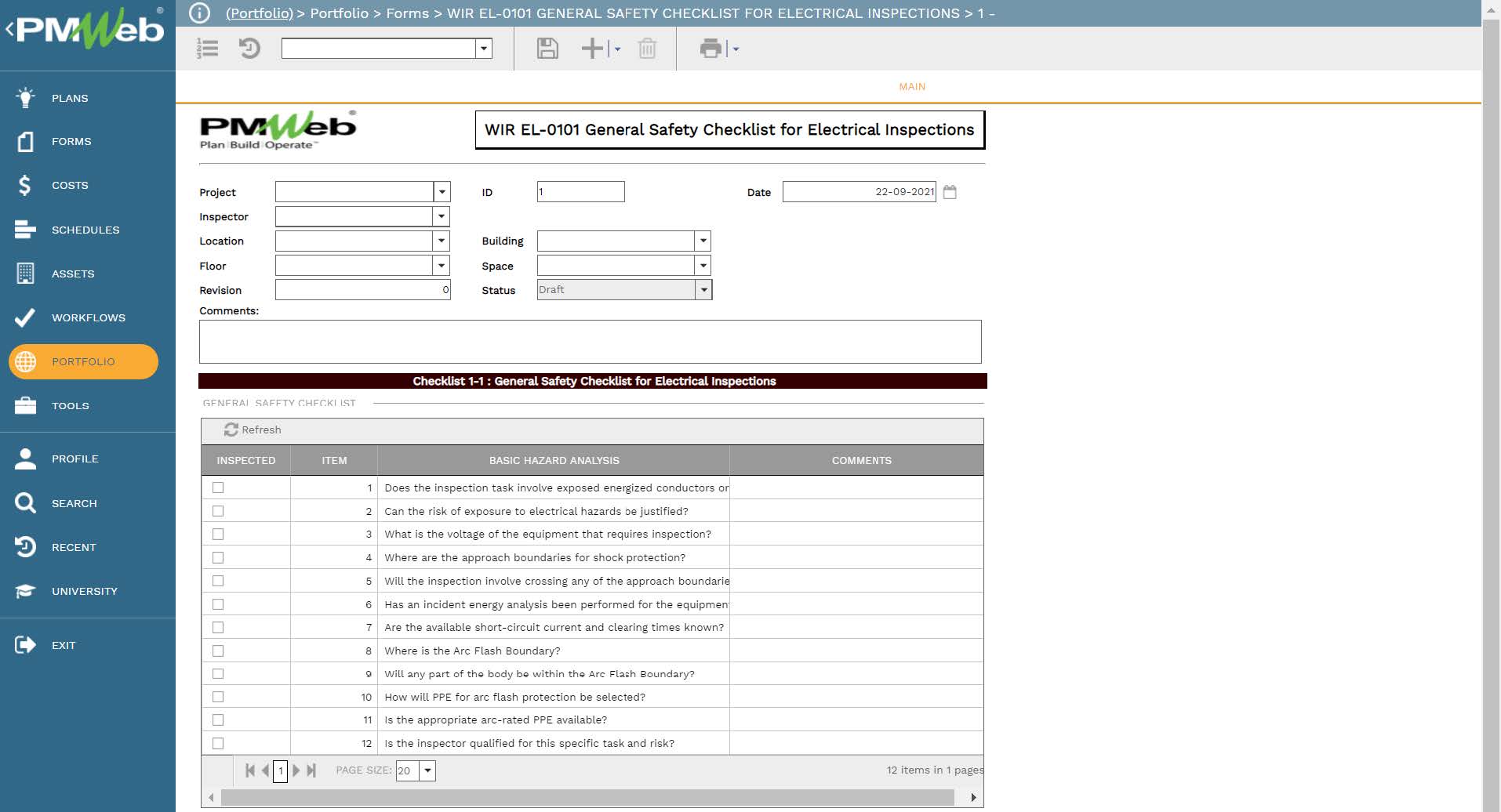

PMWeb visual custom form builder helps create the hundreds of Work Inspection Request (WIR) needed for capital construction projects. The template has a standard layout for all building systems for which the header includes:

- Details of the project

- WIR number

- WIR date

- Name of the contractor or subcontractor who has carried out the works to be inspected

- Inspection location by building, floor, and space

- Inspection date and time

- Inspector name

- Comments made

- Inspection status

- Revision if re-inspection is needed and date of inspection approval

Additional data fields like those for associated project schedule activity, BIM model object, Uniformat code, CSI code, and others can also be added.

What is unique for each WIR template, is the checklist table which includes the items that are specific to each system or component being inspected. For example, for the 77 electrical inspection checklists of the 12 groups as outlined in the above reference document, there are 77 unique templates for which each details what items to inspect for each electrical component. The table includes the items to be inspected for each Work Inspection Request (WIR) checklist, specification reference for the item to be inspected, inspection status, and inspection remarks if any.Being a 100% web-enabled zero-footprint (ZFP) application, the project team members involved in the Work Inspection Request (WIR) business process including those for electrical inspections access those WIR templates using the browser of any mobile device. This enables the team to electronically capture the inspection details immediately from the construction site.

For each building system to be inspected, a project center screen is created to group all needed Work Inspection Request (WIR) or a single page. This eases and expedites accessing those inspection checklists by the project team member who has a role in inspecting each building system. The projection center should be configured to only show the Work Inspection Request (WIR) business processes that the PMWeb user is authorized to access for the project or projects he/she is involved with. In other words, the content of the list changes depending on the PMWeb user.When any of those Work Inspection Request (WIR) business processes are selected, PMWeb displays a log of all transactions for the selected WIR. The user can view and access any of those listed transactions as well as add a new transaction.

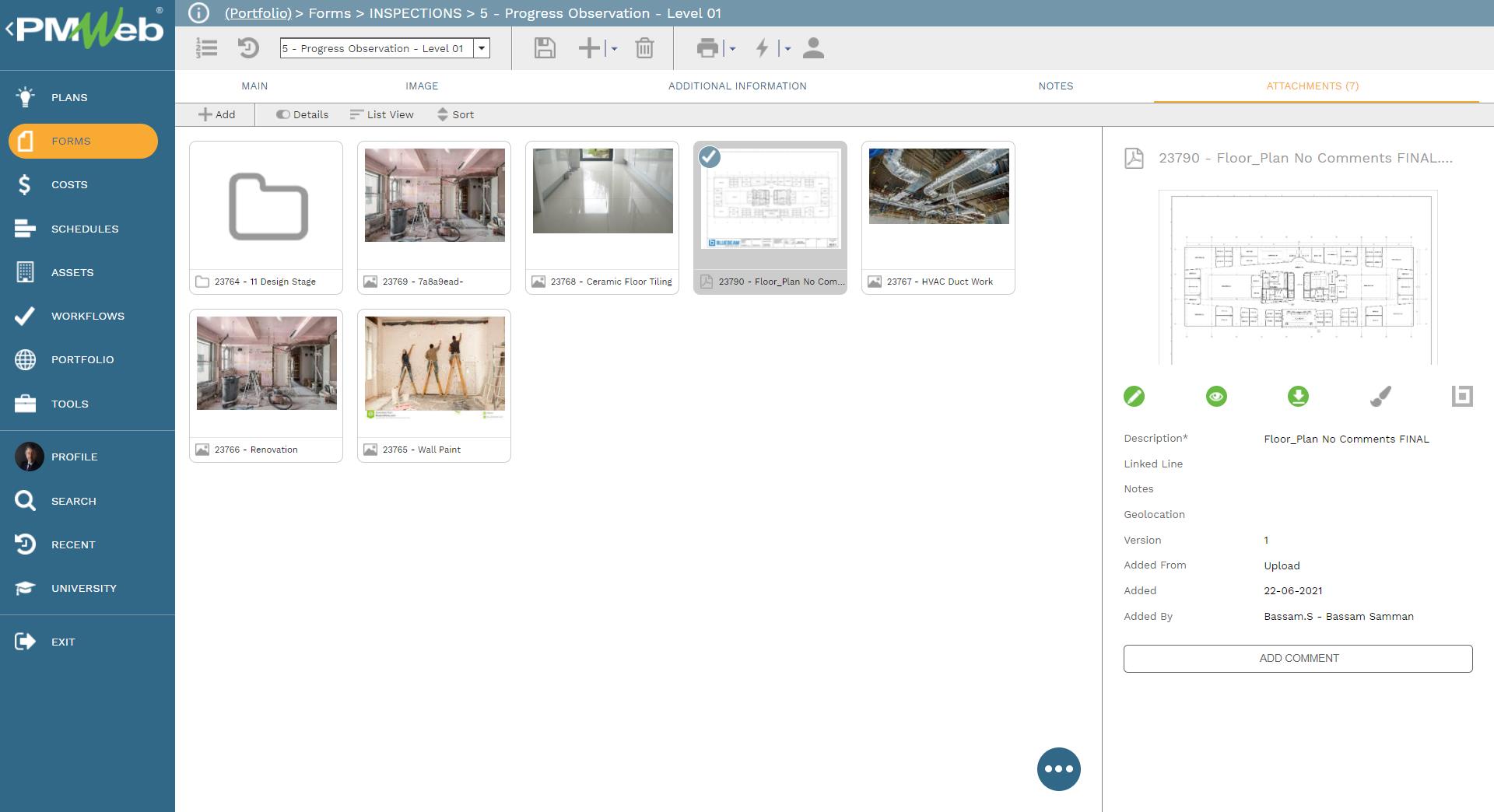

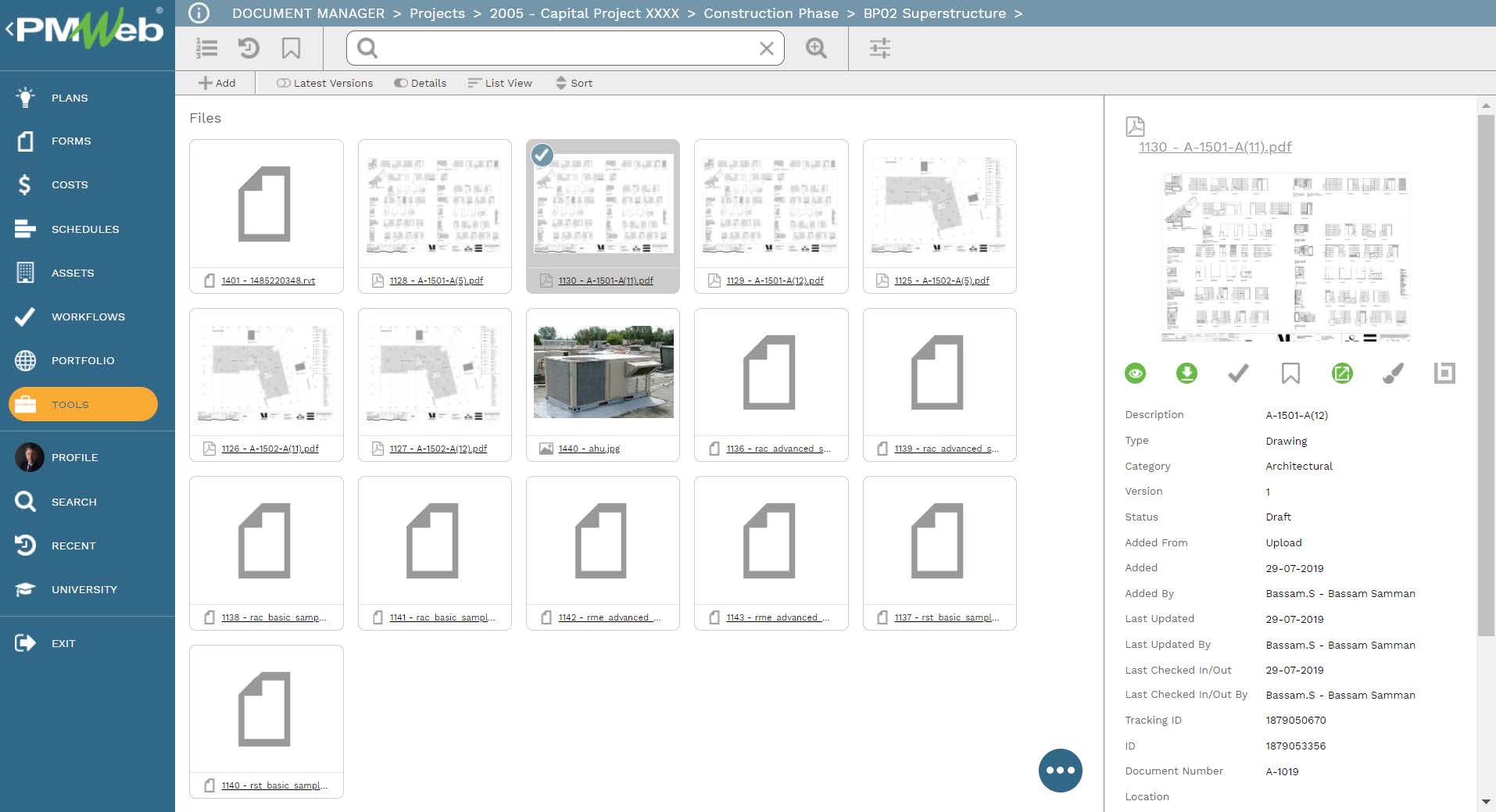

Similar to all other business processes managed in PMWeb, supportive documents that are usually associated or required for each WIR business process transaction can be attached to the template. It is highly recommended to add details to each attached document to better explain to the reader what is being attached and viewed. In addition, links to other relevant records of other business processes managed in PMWeb can be also linked to the reported progress.

It is highly recommended that all those supportive documents, regardless of their type or source, get uploaded and stored on the PMWeb document management repository. PMWeb allows creating folders and subfolders to match the physical filing structure used to store hard copies of those documents.

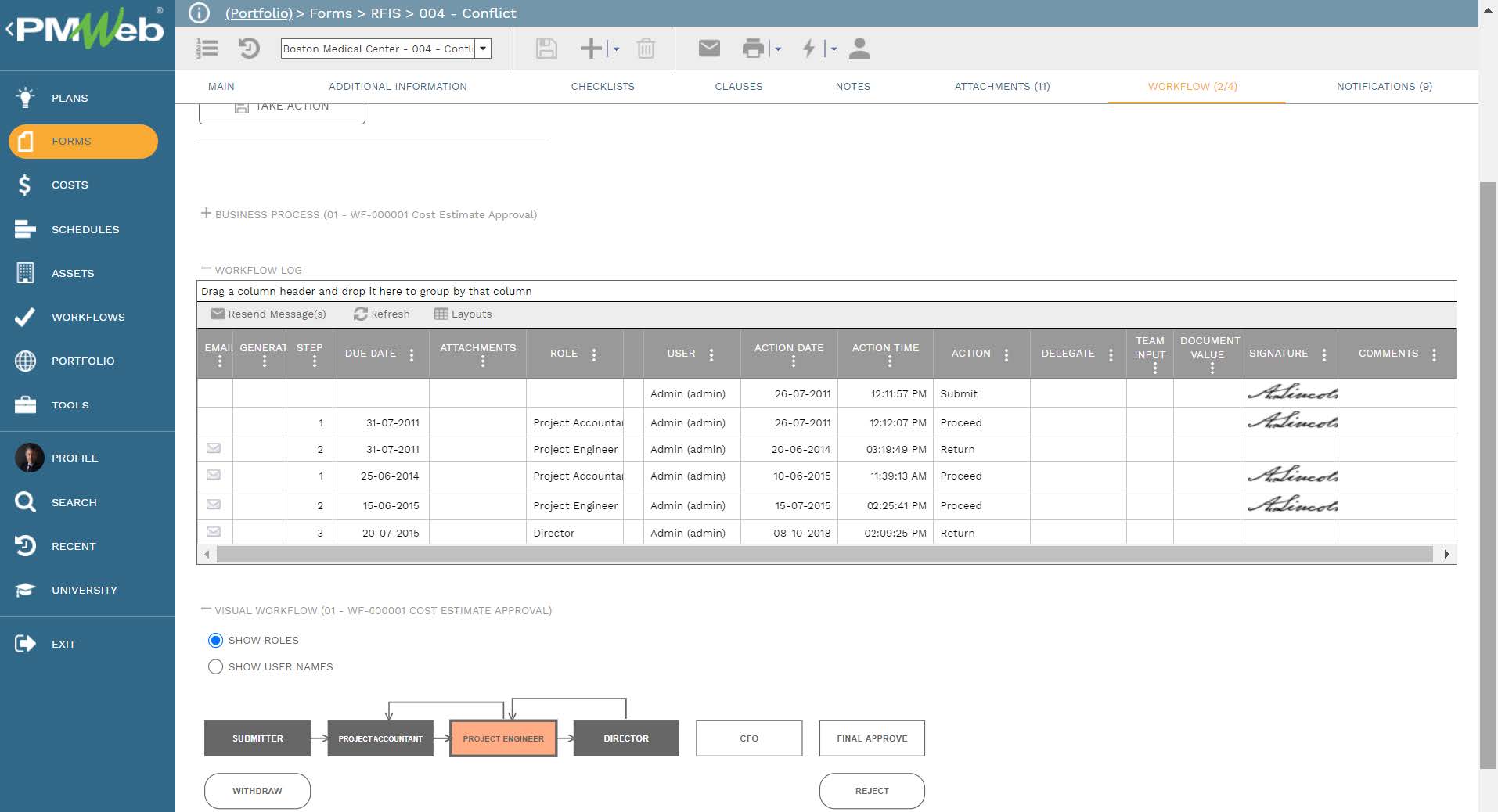

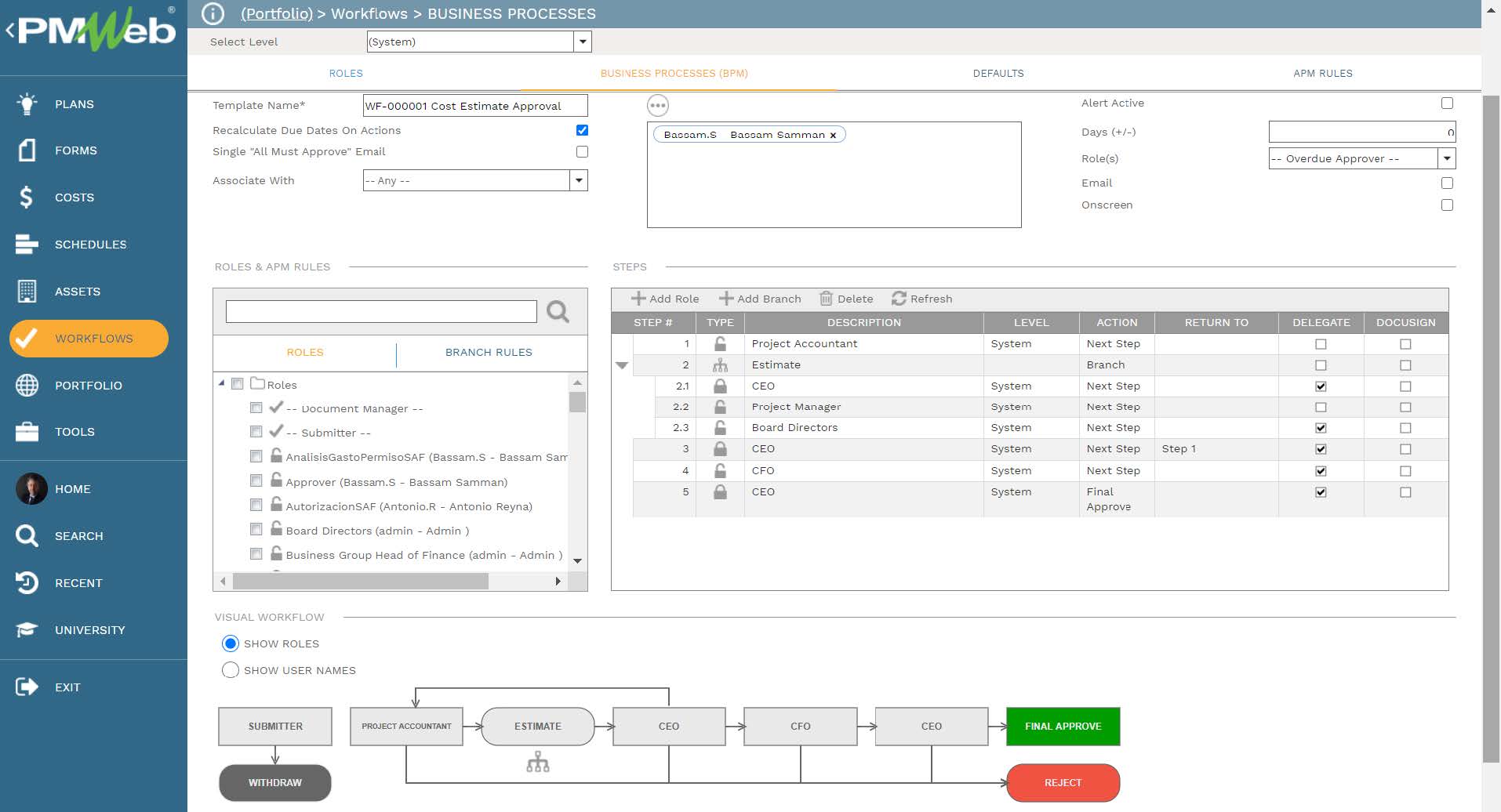

To ensure that the submit, review, and approve dates of each WIR business process transaction submission are captured, a workflow is assigned to each business process. The assigned workflow maps the submit, review, and approve tasks, roles or roles assigned to each task, task duration, task type, and actions available for the task. In addition, the workflow could be designed to include conditions to enforce the approval authority levels as defined in the Delegation of Authority (DoA) matrix.

When a WIR business process transaction is initiated, the workflow tab available on the relevant template captures the planned review and approve workflow tasks for each transaction as well as the actual history of those review and approval tasks. The captured workflow data includes the actual action data and time, done by who, action taken, comments made, and whether team input was requested.