One of the major dilemmas that face contractors on construction sites is how to verify that the estimated material resources such as steel reinforcement, cement, blocks, premix mortar, ceramic tiles, plastering, painting, false ceilings, pipes, and others for actual work in place are inline to what was originally estimated. They want to be sure that the actually consumed materials that go into a building are within the range of 2.5 – 5% usually assumed by quantity surveyors and estimating engineers while preparing the bid proposal.

On capital construction projects, usually, the detailed schedule developed by the contractors will be resource-loaded. Those include labor, material, and equipment resources. The resource-loaded schedule which must be aligned with the project’s resources estimate, is the perfect solution for monitoring, evaluating, and reporting on planned material resources usage and earned material usage for approved work in a place which is calculated from the updated percent complete values for completed and in-progress activities. Nevertheless, the actual quantities of consumed or used material resources can be best captured from the daily report where the details of work in place and all types of consumed resources are documented as well as formally communicated.

The planned, earned, and actual quantities usage of material resources for each period of the project’s duration is used to monitor, evaluate and report on how good the project’s cost estimate as well as quantifying the volume of materials consumed on the capital construction project. The analysis uses the Earned Value Management (EVM) method to quantify the material quantity variance (QV) and the Quantity Performance Index (QPI).For each material resource type, the Estimated and Actual Material Usage report details the planned, earned, actual, and estimate to complete for each period. This becomes the basis for creating the visuals for comparing earned and actual material usage, quantity variance per period and cumulative, and the Quantity Performance Index (QPI). The report includes filters to select the material resource and the periods to be reported on. The report can be for a single project or for a portfolio of projects although it is a must to have the material resource code values the same for all projects to be reported on.

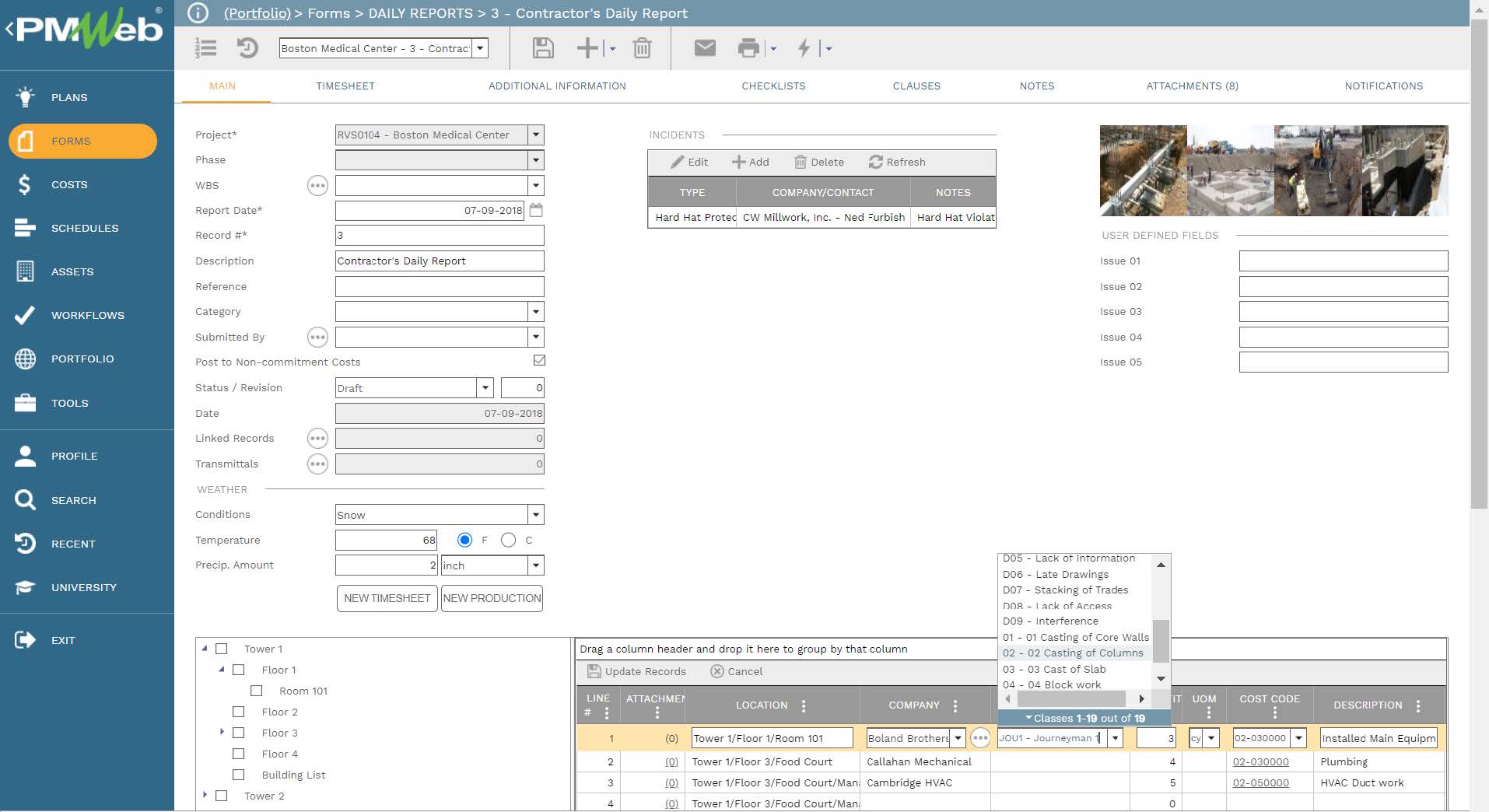

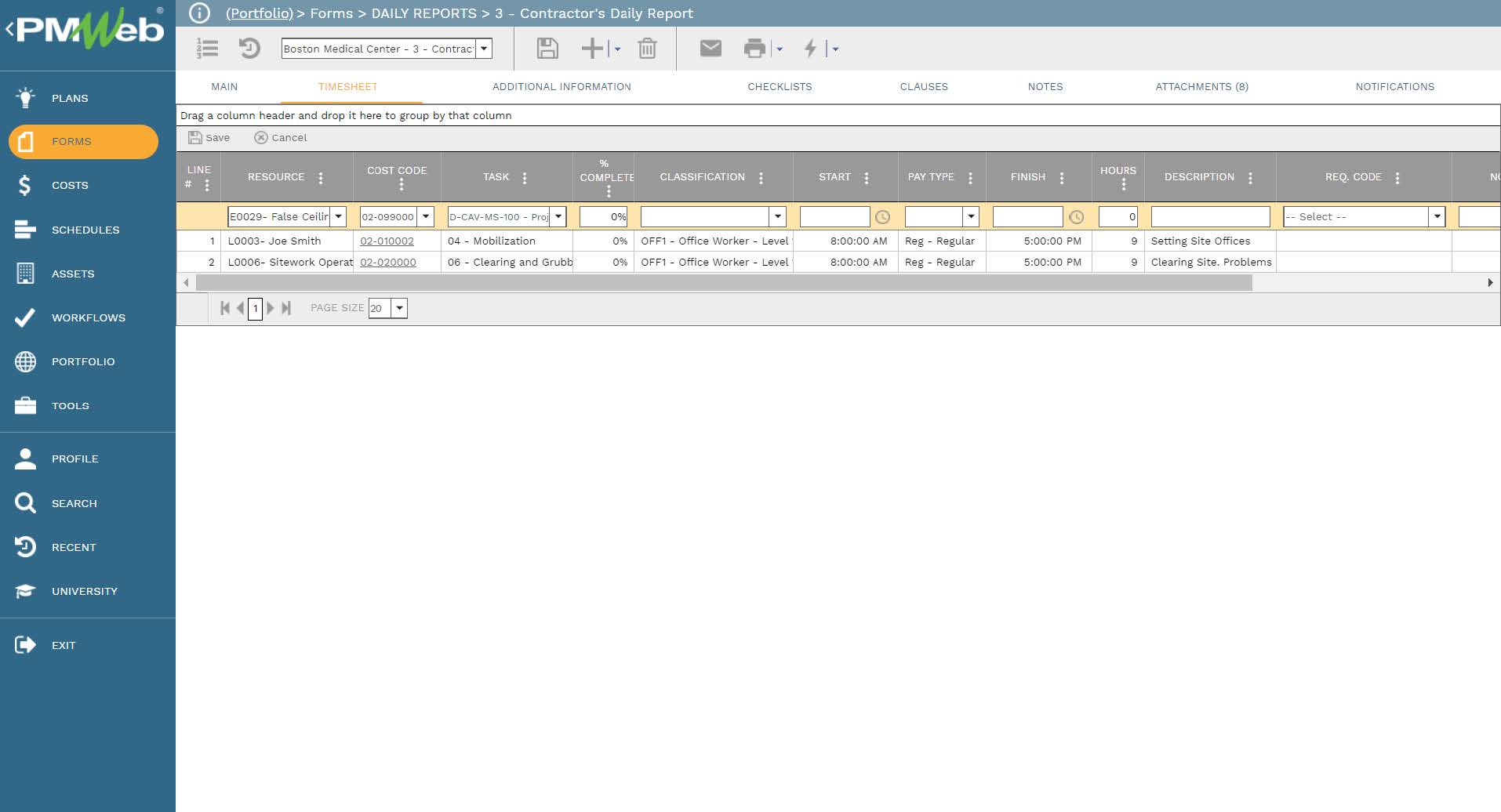

Project Management Information System (PMIS) solutions like PMWeb captures the actual quantities of material resources as well as other labor and equipment resources actually consumed on each day of each project. The Daily Report module captures the details of all activities performed on daily basis as well as the labor, material, and equipment resources consumed in performing those activities. Of course, on a capital construction project, each site engineer or site superintendent submits the daily report for the scope of work and labor crews assigned to them.

The actual quantities of labor, material, and equipment resources consumed on any particular date get captured in the Timesheet tab of the daily report. PMWeb allows associating each captured resource consumed quantities with its relevant project schedule activity. In addition, it is highly recommended for material resources to identify if the reported quantities are for approved work in place, re-do work, damaged material, etc. This is needed when it comes to verifying the accuracy of the estimated material quantities as additional material usage due to low workmanship, damaged completed work, etc. are not related to how accurate the cost estimate was. Of course, the additional quantities of materials actually consumed and wasted due to those actions could exceed 10% of what was original. Nevertheless, this is handled by actions to stop material wastage.

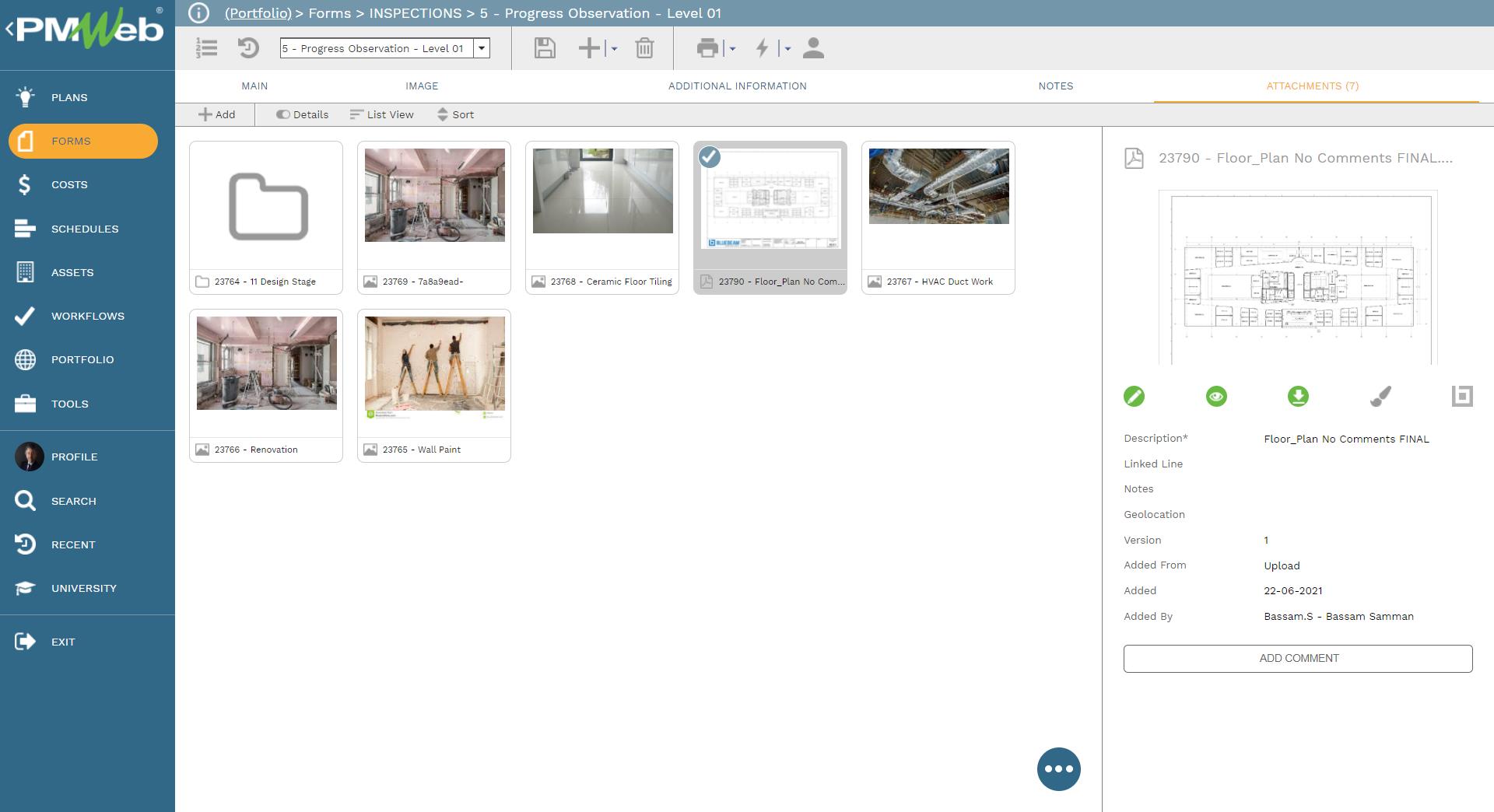

Similar to all other business processes managed in PMWeb, supportive documents that are usually associated or required for each daily report transaction can be attached to the daily report default template. It is highly recommended to add details to each attached document to better explain to the reader what is being attached and viewed. In addition, links to other relevant records of other business processes managed in PMWeb can also link to the reported progress.

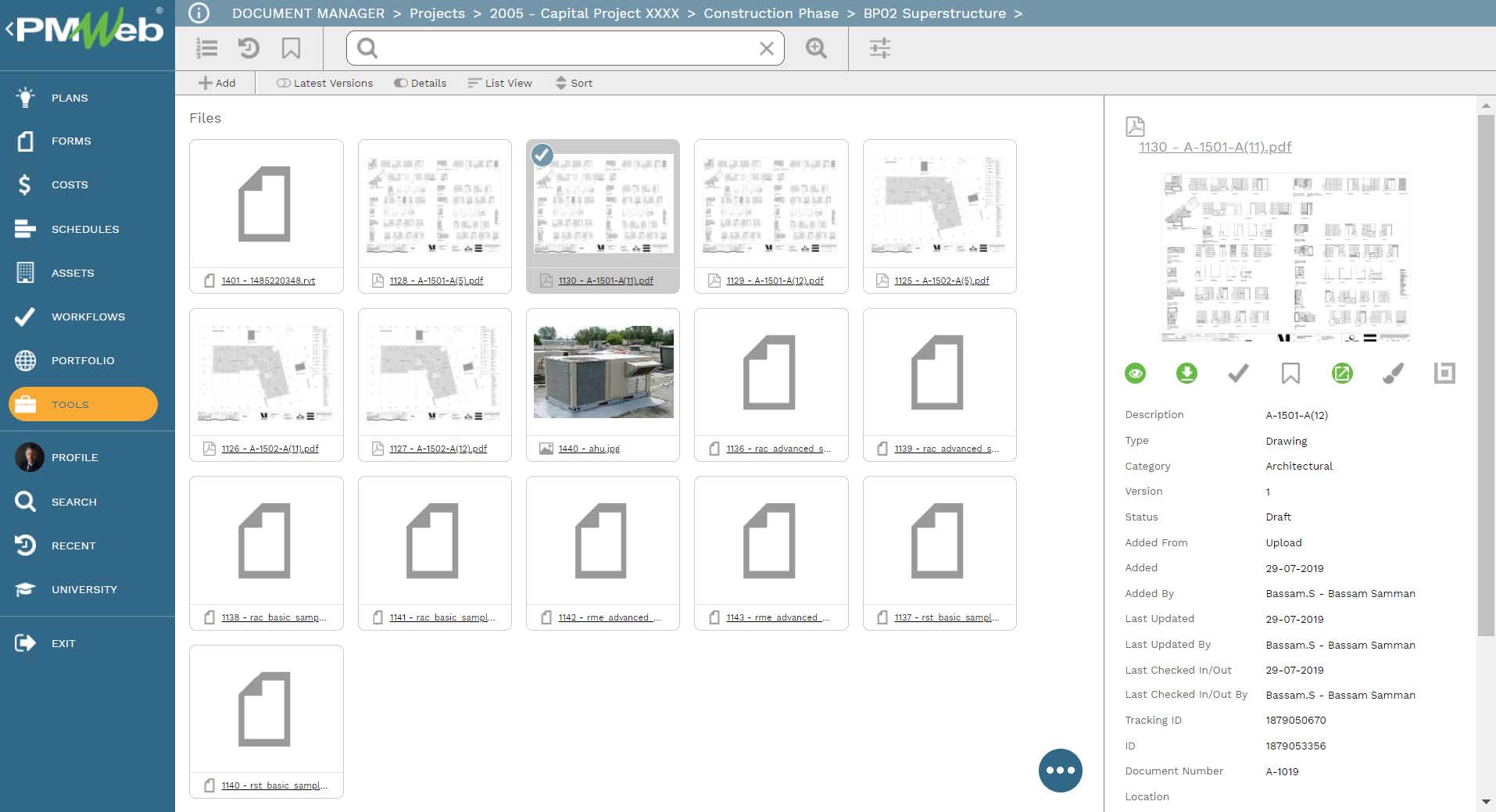

It is highly recommended that all those supportive documents, regardless of their type or source, get uploaded and stored on the PMWeb document management repository. PMWeb allows creating folders and subfolders to match the physical filing structure used to store hard copies of those documents.

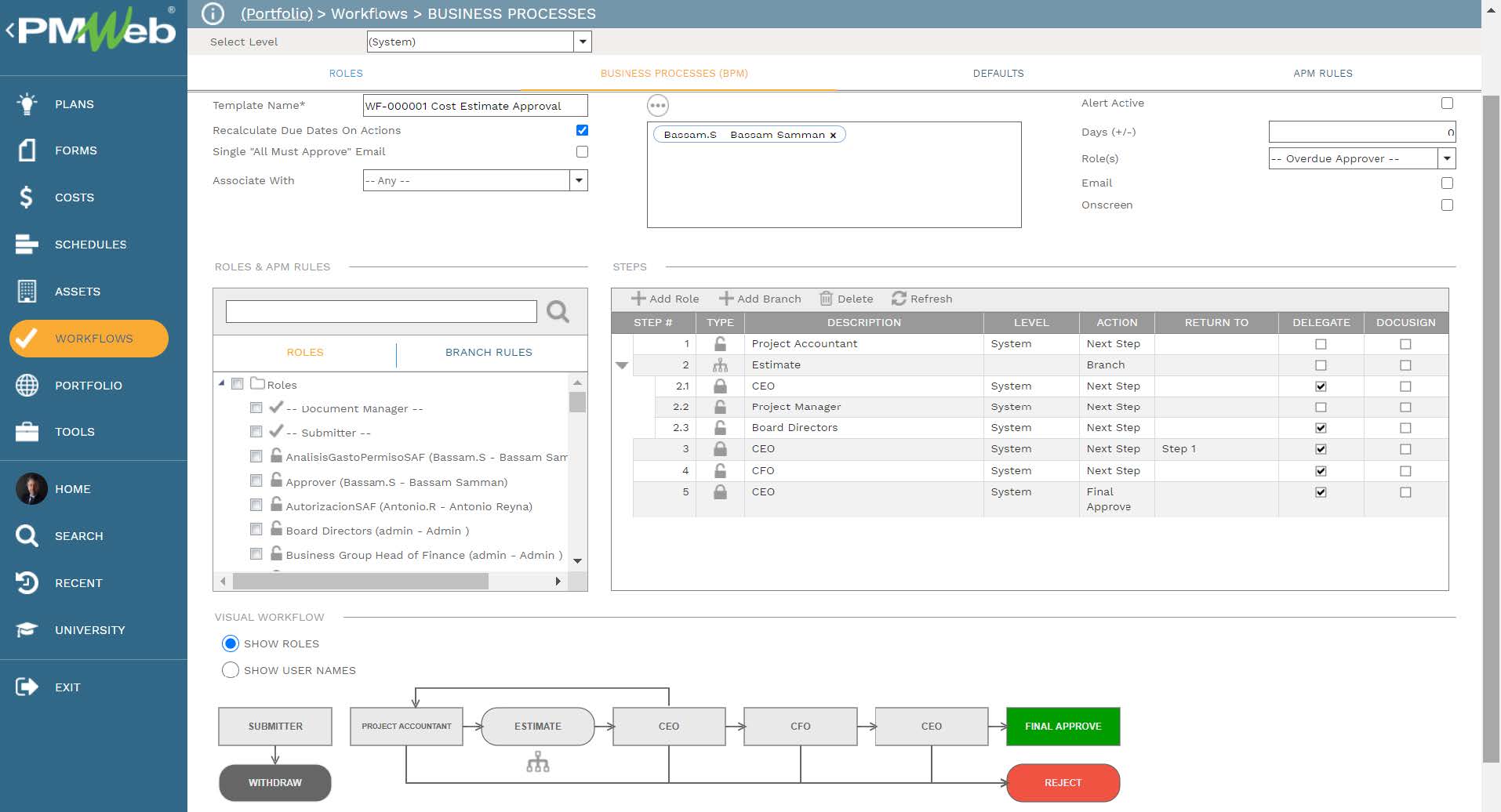

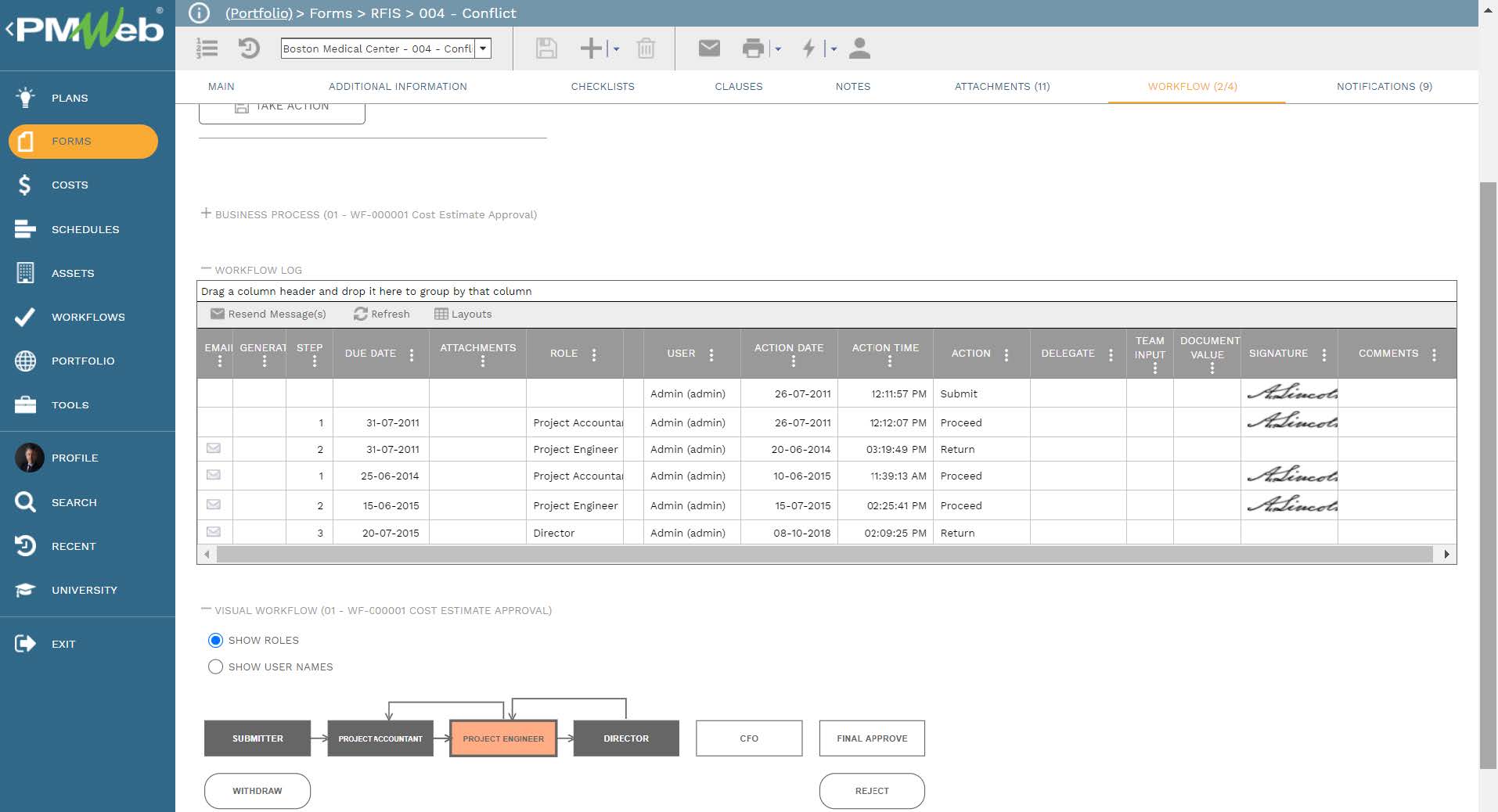

To ensure that the submit, review, and approve dates of each daily report transaction submission are captured, assign a workflow to each business process. The assigned workflow maps the submit, review and approve tasks, roles or roles assigned to each task, task duration, task type, and actions available for the task. In addition, the workflow can be designed to include conditions to enforce the approval authority levels as defined in the Delegation of Authority (DoA) matrix.

When a daily report transaction is initiated, the workflow tab available on the relevant template captures the planned review and approve workflow tasks for each transaction as well as the actual history of those review and approval tasks. The captured workflow data includes the actual action data and time, done by who, action taken, comments made, and whether team input was requested.

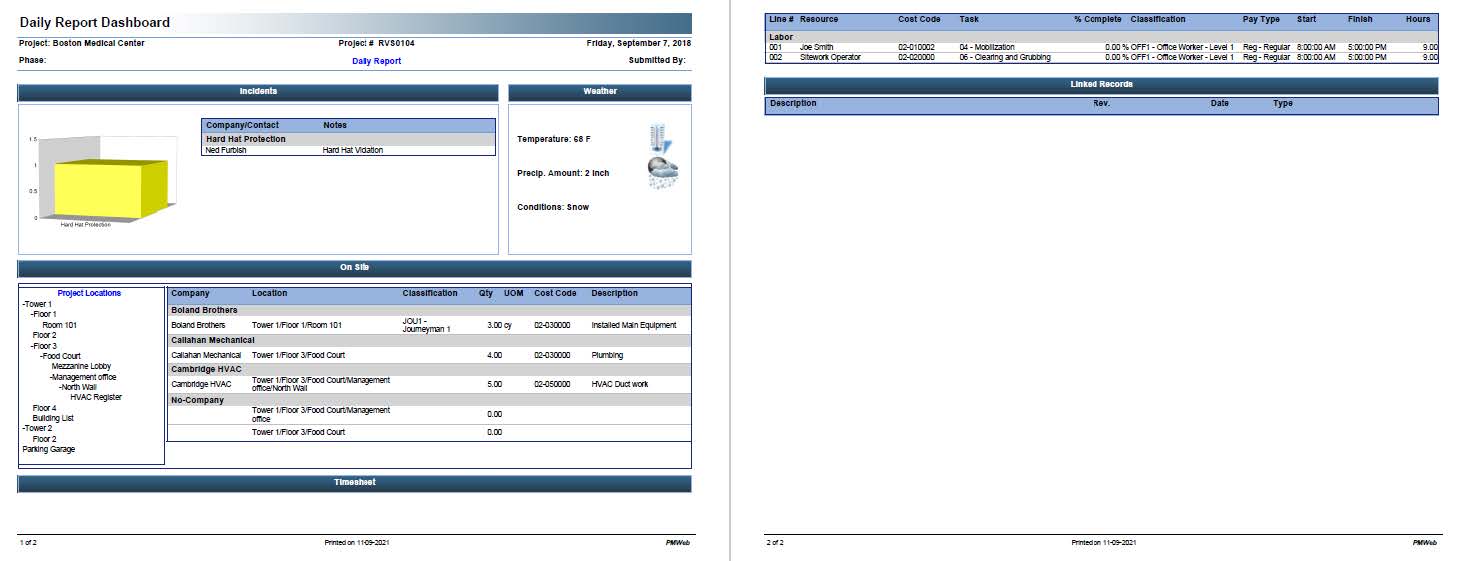

The completed daily report can be printed so it can be formally communicated to the project owner or his authorized representative on the project site. The layout and format of the daily report can be designed to match the branding required set for each project. The daily report template can also be designed to consolidate the daily report’s data captured by the different site engineers and site superintendents to enable formally submitting a single daily report to the project owner.