Electrical systems in most Buildings are the most critical to maintaining building operations. Electrical systems are the source for providing energy to all electro-mechanical, communication and security, conveying, and other systems in the building including HVAC, lighting, security, safety, communication, and monitoring systems. Commissioning of electrical power systems is important because most electrical failures often occur as catastrophic events and are not detected until a fault or failure occurs.

Cold Testing is the term used for all inspection and testing required in low voltage electrical installations (main, sub-main, distribution boards, and Motor Control Centers) prior to energization. Cold Testing is part of the construction testing or preliminary testing and commissioning Work.

Upon completion of the Cold Testing and inspections as well as the testing required for the electrical equipment by the Suppliers or Manufacturers, electrical system energization takes place. Energization is always carried out by the Main Contractor electrical installation team in coordination with all electrical equipment suppliers and supervision of the Main Contractor’s Safety Management Team, Project Manager, and Commissioning Authority. Energization starts one-by-one from the main equipment source and down to the last distribution board.

To ensure that the pre-energization testing had been completed in accordance with the project specifications and other testing and commissioning requirements, it is highly recommended to use predefined pre-energization checklists for each electrical equipment type to be tested. Those would include pre-energization checklists for HV/MV Switchgear, Switchboards, Transformers, MV/LV Automatic Transfer Switch, UPS, MCC/Distribution Boards, HV/LV Cables among others.

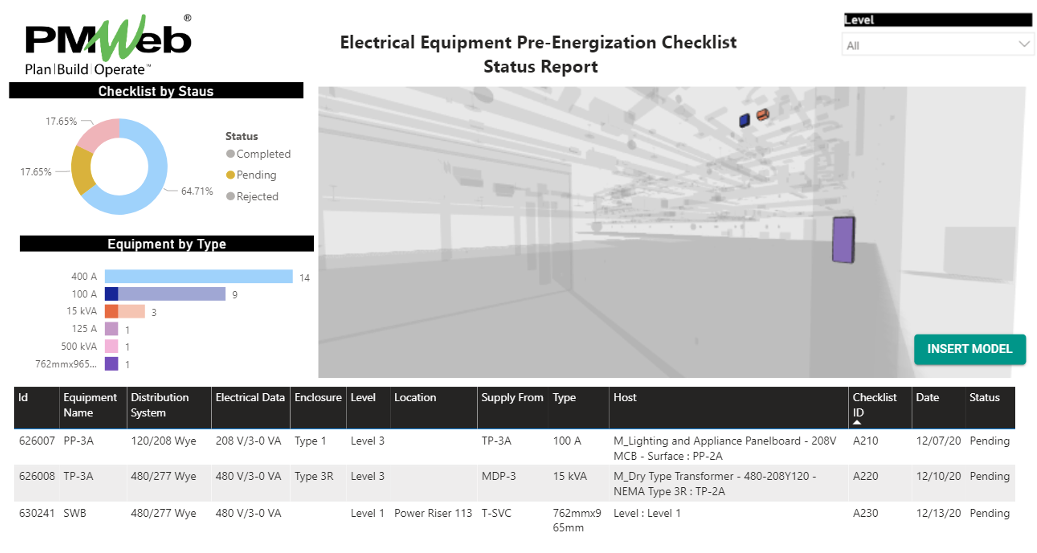

For projects that use Building Information Modelling (BIM), associating the checklists with the electrical equipment and cables that are part of the BIM model will improve the monitoring, reporting, and visualizing the status of the pre-energization checklists. This reporting will be designed using MS Power BI business intelligence and data visualization tool. The 3DBI visual developed by KG-DEV called 3DBI (https://kg-dev.be/) will be used to display the BIM model for Electrical System extracted from Autodesk Revit in MS Power BI. To ensure that the pre-energization checklists are associated with their relevant BIM object, a field for BIM ID will be added in the checklists. The pre-energization checklists will be created and managed using PMWeb Project Management Information System (PMIS) solution.

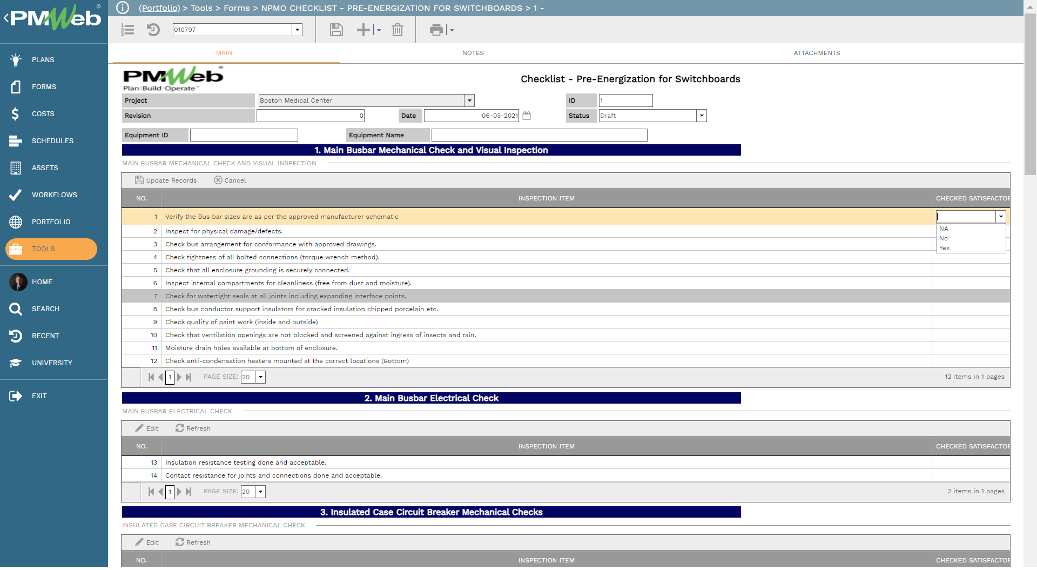

PMWeb visual form builder will be used to create the pre-energization checklists which will be unique for each type of electrical equipment to be tested. The checklist will include a field to capture all details of each piece of equipment to be tested including the BIM model object ID that relates to the equipment to be tested. In addition, the checklist will detail all items to be tested which will be grouped by their relevant categories. For each item that will be inspected, the inspector needs to confirm if checking that item was satisfactory or not. The checklist can be accessed from any smart device with an internet connection to enable completing those checklists on the construction site.

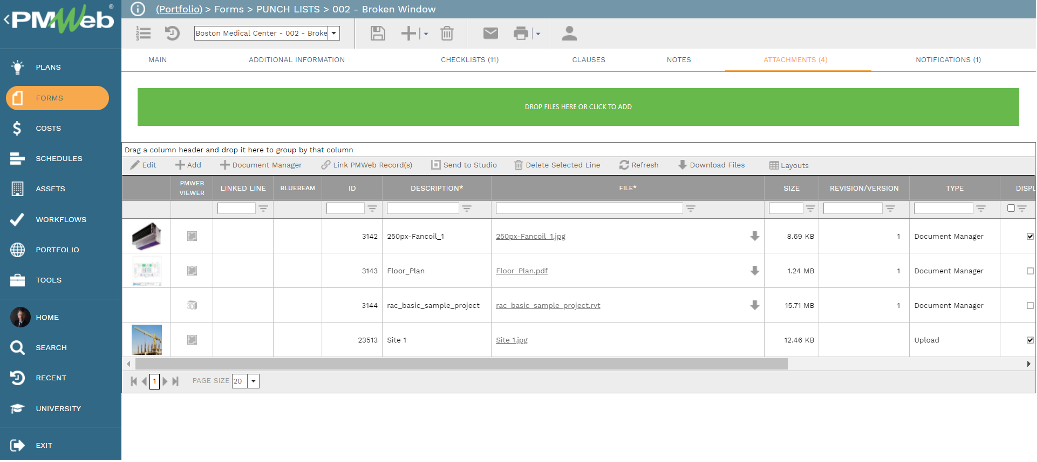

All documents and pictures that are relevant to each electrical equipment need to be attached to its relevant pre-energization checklist form. When using a mobile device with a built-in camera like an iPad, when the user clicks on the attach button, the user will be given the option to take a picture or video. It is highly recommended to upload and store all documents, pictures, and videos into their assigned folder or subfolder on the PMWeb document management repository.

In addition, PMWeb viewer can be also used to add comments and remarks to those documents when needed. The project team can append the attachment list with other documents as well as link other PMWeb records and imported email communications.

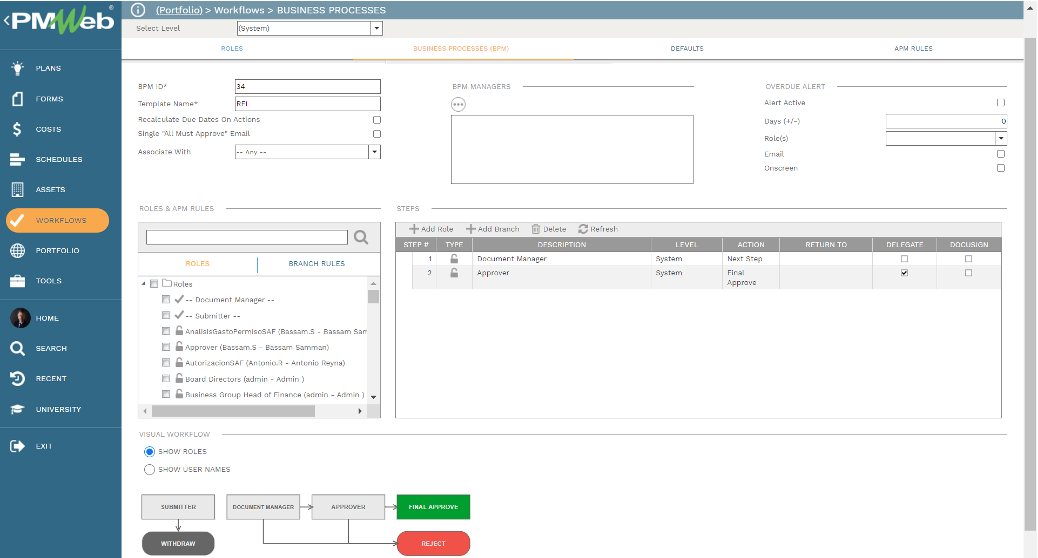

To ensure that the pre-energization checklists are formally reviewed and approved before they can be considered as closed, a workflow will be assigned to each pre-energization checklist form. Although the submit, review and approve workflow could be the same for all pre-energization checklists, nevertheless, there is the option to have a unique workflow for each electrical equipment type. The workflow will map the submit, review, and approval tasks along with the responsible individual for performing the task, time allotted to complete the task and available actions to be taken. The workflow could include conditions to enforce the required approval authority levels.

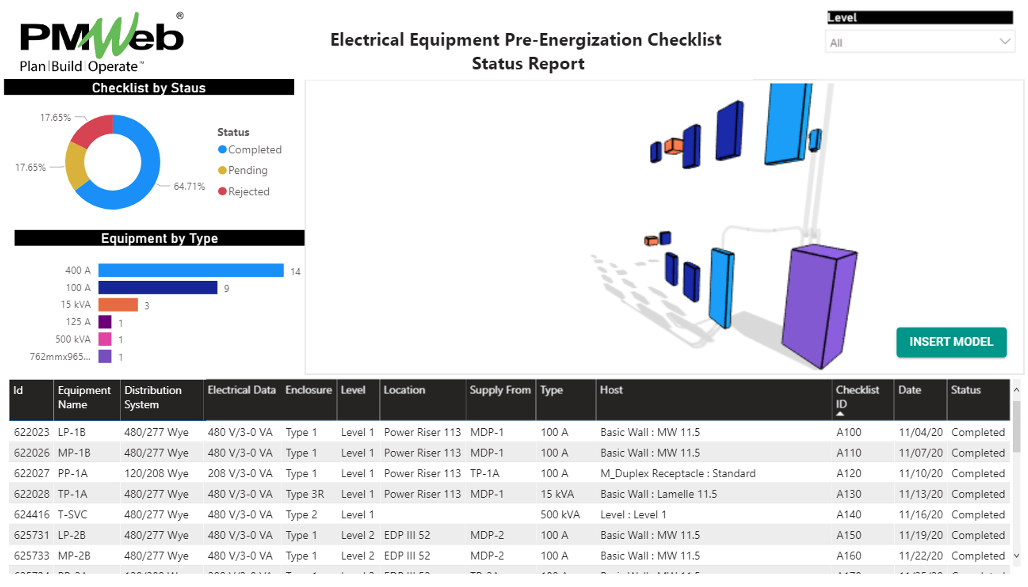

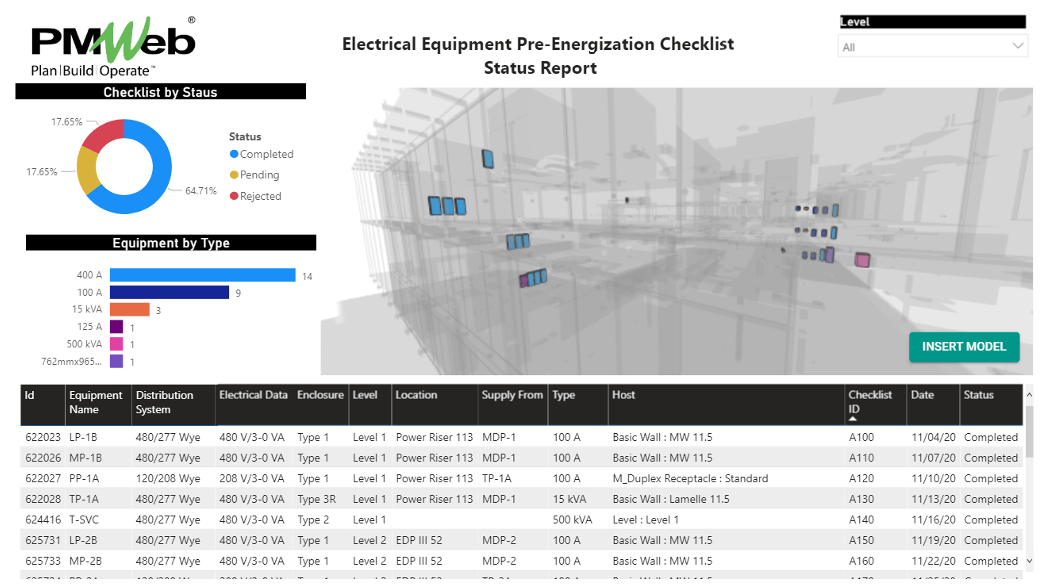

The interactive Electrical Equipment Pre-Energization Checklist Status Report will enable the project stakeholders to identify equipment by type, level, status of checklist among others. For example, if the report reader clicks on the pending checklists using the “Checklist by Status” visual by clicking on the “Yellow” slice of the donut, the BIM Model visual, the Equipment by Type Visual, and the Equipment Register will be automatically updated to reflect the selected filter. The same approach will be also true for other filters.

The Electrical Equipment Pre-Energization Checklist Status Report can also be designed to use a BIM visual that shows the electrical cabling linking the electrical equipment which also needs to be tested. For this BIM Visual it will be recommended to hide all floors and other BIM assets shadows. The main objective of having the BIM Visual is to provide the report reader with a better understanding and visualization of the different electrical equipment that needs to be tested before the building gets energized.