The earned value management (EVM) method provides an easy-to-visualize solution to monitor and report the performance of Engineering-Procurement-Construction (EPC) projects. In addition, it is a perfect solution for monitoring and reporting the performance not only for a single project but for a portfolio of EPC projects. Nevertheless, since the majority of awarded EPC projects, at least in the Middle East region, are usually based on Lump Sum Turnkey (LSTK) contract agreements, the Actual Cost (AC) measure will not apply to the EPC Project Owner as the Earned Value (EV) for completed work in place will be always equal to the Actual Cost (AC) value. Of course, this will not be the case if the total cost of an EPC project would also include the cost of activities performed by the EPC project owner as the cost of those services could differ from what was original.

Nevertheless, this will not be the case for the EPC contractor will managing all commitment and non-commitment costs that could be incurred on the EPC project. This will have a direct impact on the project’s Actual Cost (AC). For the sake of this article, it is assumed that whether the EPC project was monitored and controlled by the Project Owner or the EPC Contractor, Actual Cost (AC) could differ from the Earned Value (EV).

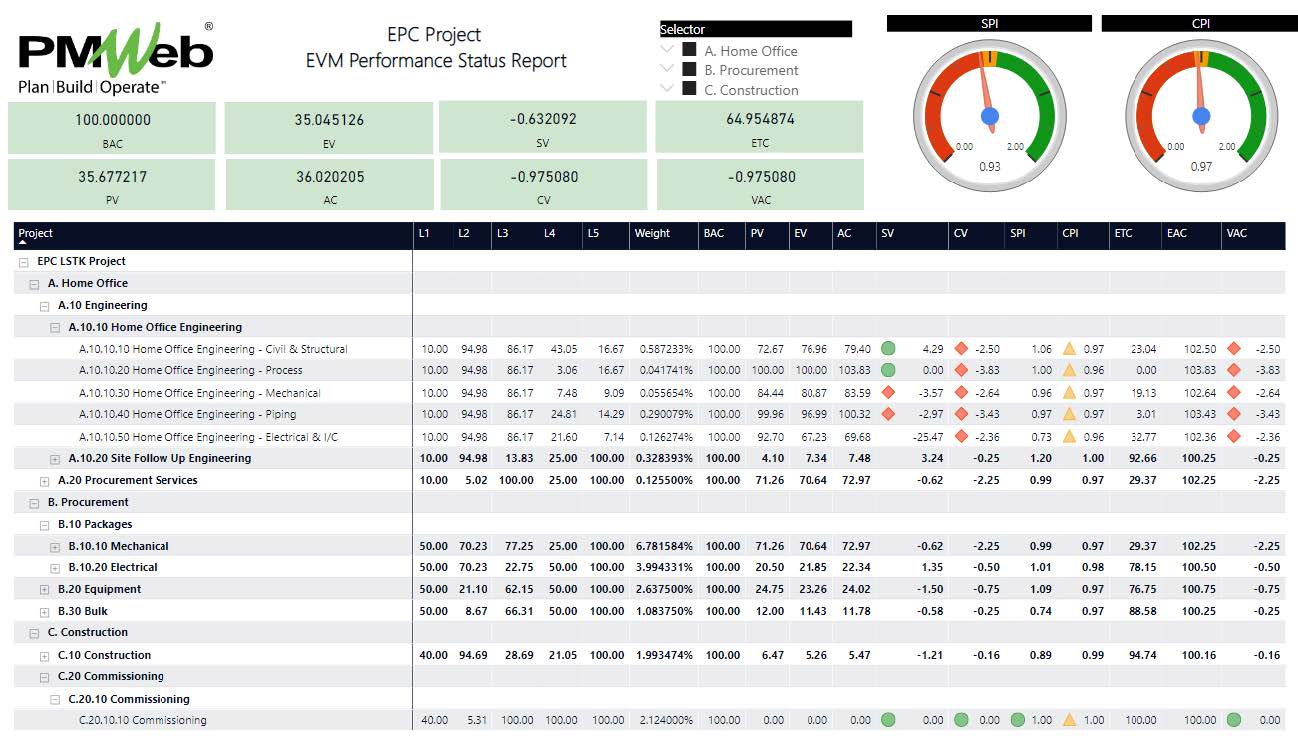

The planned performance for an EPC Project will be based on the calculated Planned Value (PV) for each period in accordance with the approved Integrated Baseline Schedule. The schedule activities will be loaded with their weight values based on the agreed weight values assigned to each project stage, category, work package, drawing among other project deliverables. This will be aligned with the project’s Work Breakdown Structure (WBS) levels.

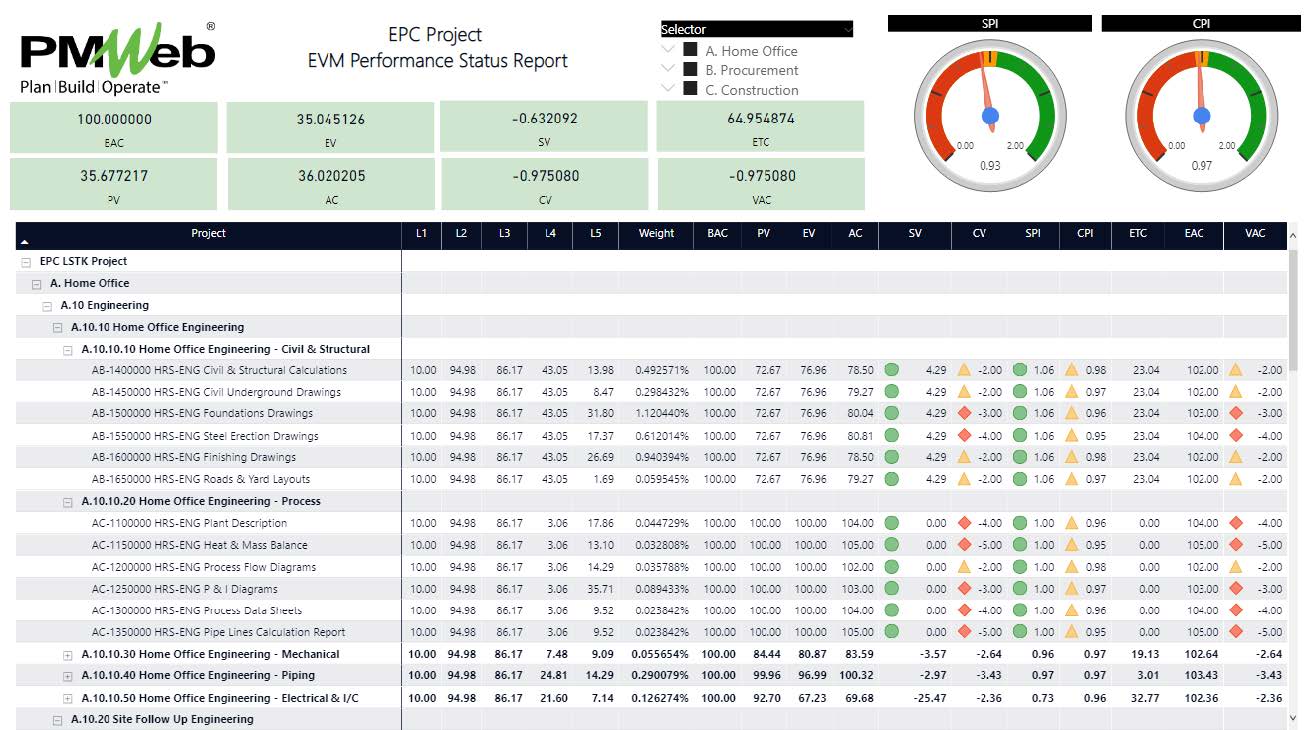

The Earned Value (EV) achieved for each deliverable will be based on the performance earning rules set by the Project Owner. There will be different rules for reporting progress for engineering, procurement, and construction deliverables. Details of engineering and procurement deliverables were detailed in earlier articles. As for the construction deliverables, the Earned Value (EV) will be based on the rules for reporting the actual performance of on-site construction activities.One of the key advantages of using Earned Value Method (EVM) for monitoring and reporting the EPC project performance, is the ability to drill down from the project level to each engineering, procurement, or construction stage. The report reader can then drill down to each group within a stage like packages, equipment, and bulk for the procurement stage. This will be followed by drilling down to the discipline level including civil, mechanical, electrical, etc.

A Project Management Information System (PMIS) like PMWeb will be used to manage, monitor, evaluate and report on the many business processes needed to manage an EPC project. PMWeb will be also used to manage, monitor, evaluate and report on the deliverables for engineering, procurement, and construction stages.

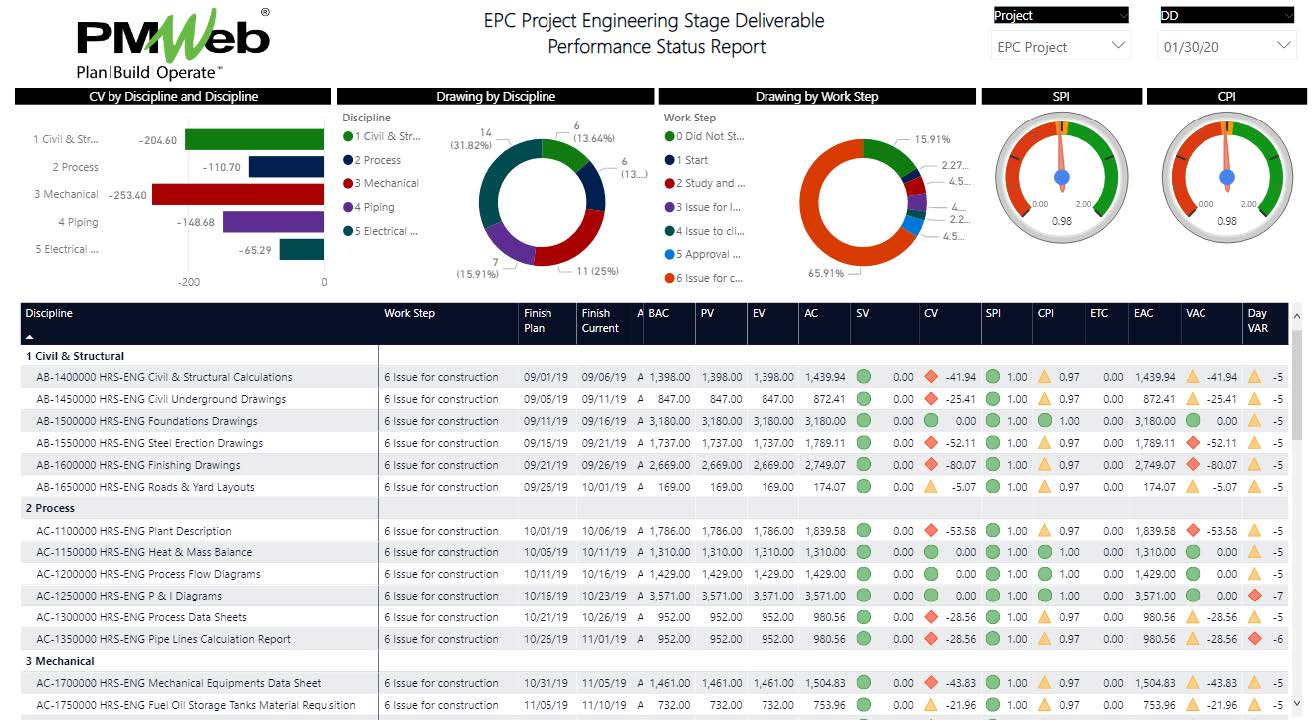

In the article titled “Using Earned Value Management (EVM) for Reporting the Performance of Engineering Deliverables on Engineering-Procurement-Construction (EPC) Projects”, it was detailed how engineering deliverables will be managed, monitored, controlled, and reported on using the EVM method.

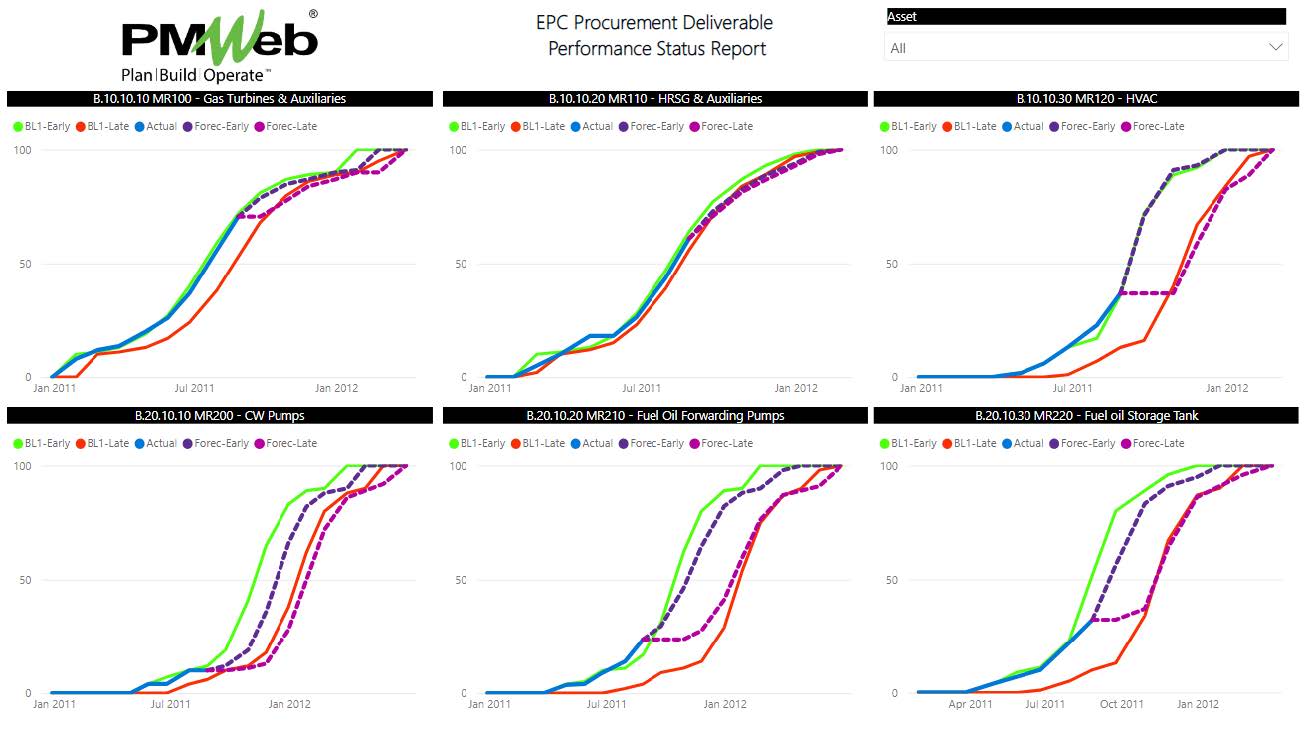

Similarly, the article titled “Monitoring, Evaluation and Reporting the Earned Performance for Procurement Deliverables on EPC and LSTK Contracts”, detailed how to manage, monitor, and report the planned and actual progress achieved for procurement stage deliverables. By multiplying the planned and actual progress valued with the project’s Budget at Completion (BAC), the Planned Value (PV) and Earned Value (EV) measures will be calculated.

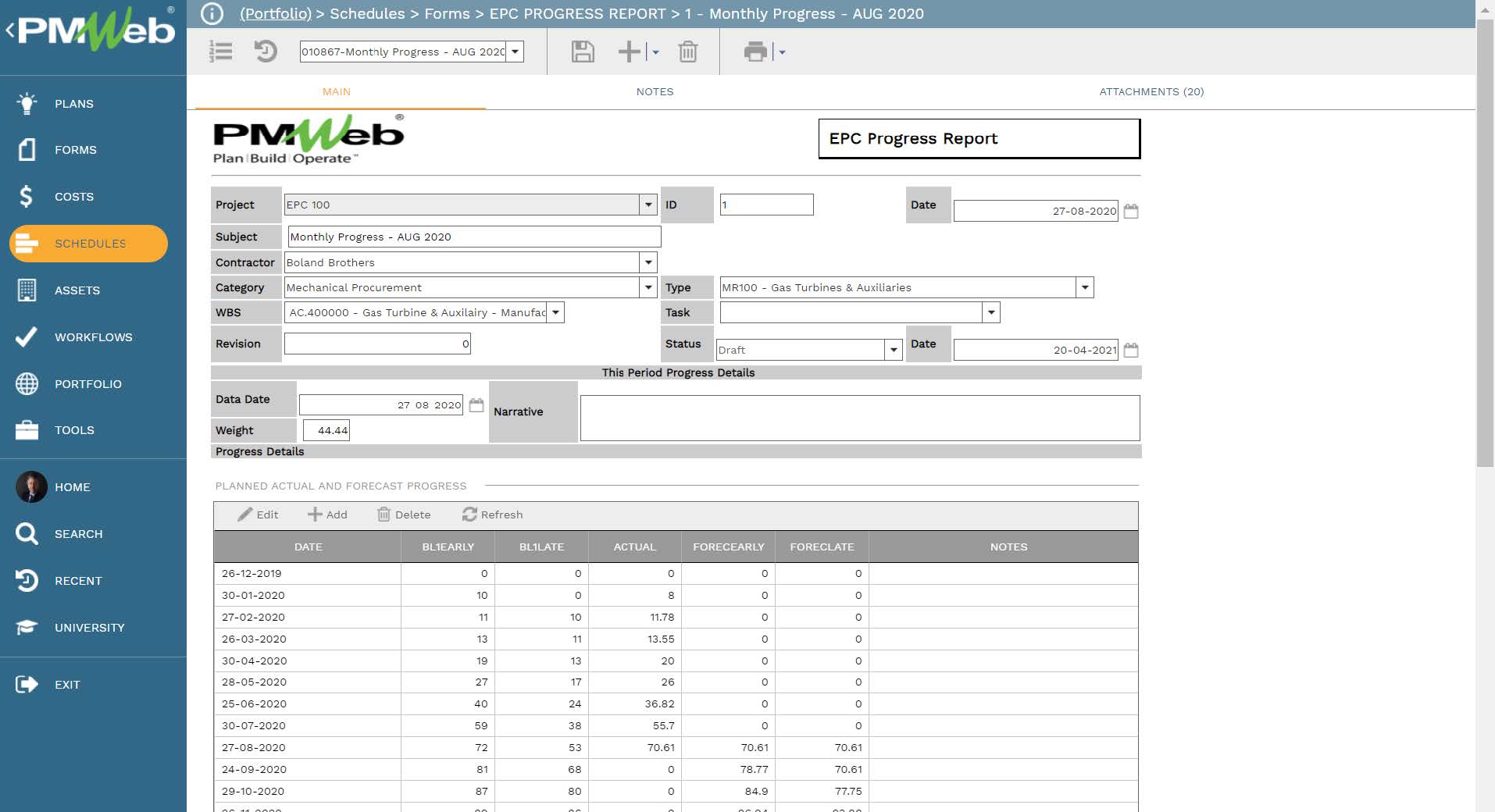

The same approach used for reporting progress for procurement stage deliverables will be also used for construction stage deliverables. The EPC progress report will be used to capture the planned early and late dates progress percentages which will be extracted from the approved Integrated Baseline Schedule. The actual progress percentages will be captured in accordance with progress earning rules that will be pre-agreed with the EPC contractor.

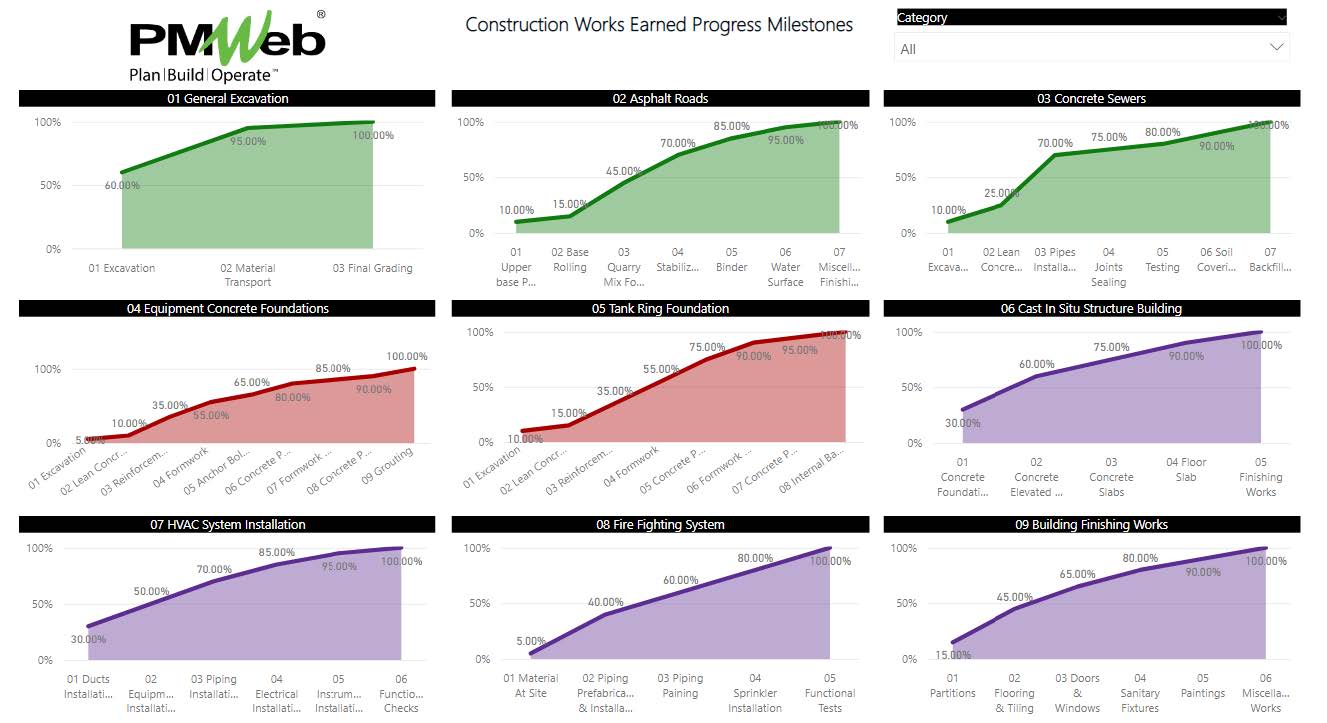

Similar to the procurement progress form, the construction stage progress form will include another table to capture the details of the reported actual progress. The EPC contractor will report the achieved progress against each construction work package based on the agreed step weights set for each. Those steps and associated weight could differ from one project owner to another. Nevertheless, for the same project owner entity, it is highly recommended to standardize those steps and weights across all EPC LSTK projects. The chart below details the earned progress weights for Site Preparation & Underground Works, Civil Works, and Buildings work packages.

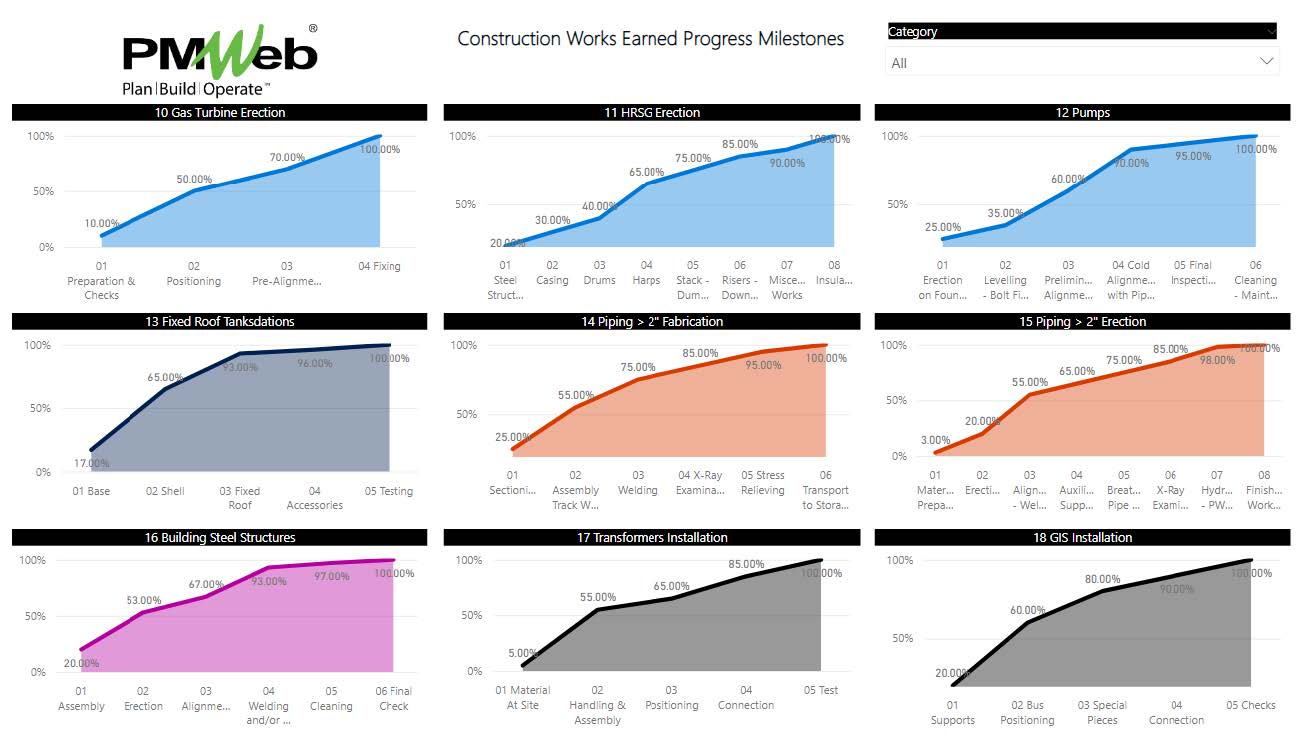

On the other hand, the chart below details earned progress weights for Mechanical Erection, Storage Tanks. Piping Prefabrication and Erection, Steel Structures, and Electrical Installations construction work packages. Other earned progress weights need also to be done for Insulation and Testing & Commissioning construction work packages.

Depending on the level of details of progress data captured for the engineering, procurement, and construction deliverables, the EVP Performance report can be further detailed to allow drilling down to each deliverable within each discipline like those for engineering drawings. The EVM performance report displayed below details the performance status of engineering deliverables for the Civil and structural discipline as well as Process discipline for Engineering Deliverables.